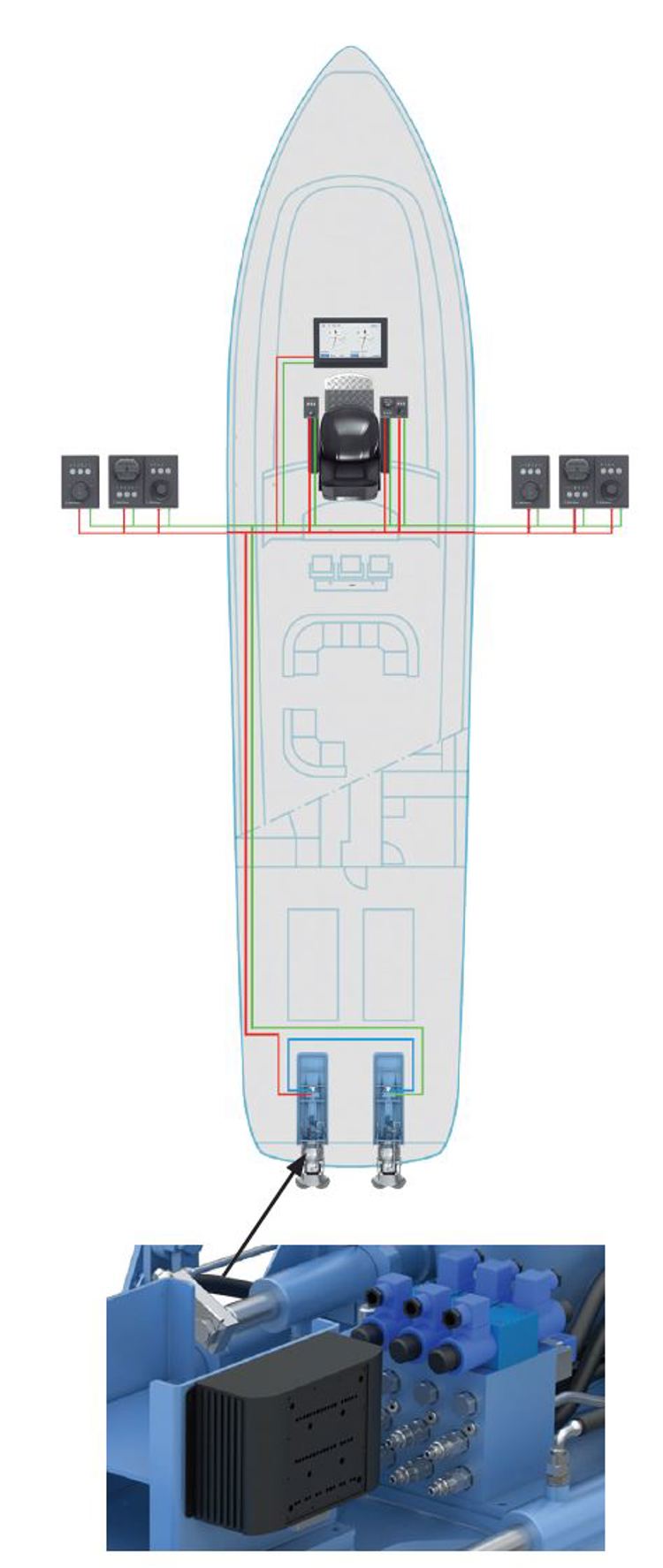

Compact Control System

Compact Control System

Features and benefits

For the designer

- Compact design with standard dimensioning and interfaces to all main equipment onboard.

- Pure plug and play principle with minimal amount of loose components.

- Simplified variable system configurations available

For the yard

- Factory calibrated components with minimal startup requirement.

- Modular CAN-BUS design, with plug-in control devices and display

- Hydraulic valves, pipes, controllers and feedback sensors are installed on jet at factory (steel- and aluminium series)

- Tested and pre-calibrated modular design

For the operator and owner

- Full redundancy in power supply, controls and Waterjet propulsion line

- Fully separated backup system

- Easy and safe to use

Waterjet configurations

- Single installation

- Twin installation

- Twin + Booster installation

- Quad installation

Control station configurations

- 1 to 3 control station indoor or outdoor

- 1 lever and 1 steering device per station

- Optional two steering devices for station 1

- Joystick possibility at all stations

- Touch screen for non-critical functions

- Independent indication or backup system available

Main components

- Marine I/O controller

- 10” Graphical User Interface

- Visual indication of waterjets operation

- Activation of automatic interceptor control

- Alarms list

- Basic settings and adjustments

Control panels available

- Lever unit

- Steering device; Steering knob, Steering tiller, Steering wheel

- 3-axis joystick

- Bow thruster control

Backup system

In case additional backup system is needed, every steerable jet is equipped with backup controller. Backup system control devices available for one to three station.

Alarms

Various alarms are available, depending on waterjet setup. Alarms are displayed on the graphical user interface or optionally over serial line.

Interfaces

- Engine command; 4-20mA or 0-5V

- Gear clutch control; engage, disengage and backflush

- Autopilot steering signal; 4-20mA, ±10V or solenoid drive

- Bow thruster command; 4-20mA or ±10V or PWM for hydraulic bow thruster

- Warning and failure relay alarms for each waterjet

- RS-422 serial interface according to NMEA 0183 for Voyage Data Recorder

- DP-interface (optional)

- Interceptor controls (optional)

Lifecycle support for your vessel

-

24/7 Technical support

Our 24/7 technical support team is there to help at any time, day or night, wherever your vessel is.

Our 24/7 technical support team is there to help at any time, day or night, wherever your vessel is.

-

Conversions, retrofit and refit

Upgrading and enhancing your vessel’s performance.

We understand the importance of having the right parts, available in the right place, at the right time.

-

Training

Maximise crew efficiency and reduce downtime with expert training.

Ensure that your crew is properly and thoroughly trained. This will reduce operational risk, downtime and maximise return on asset investment.

How can I help you?