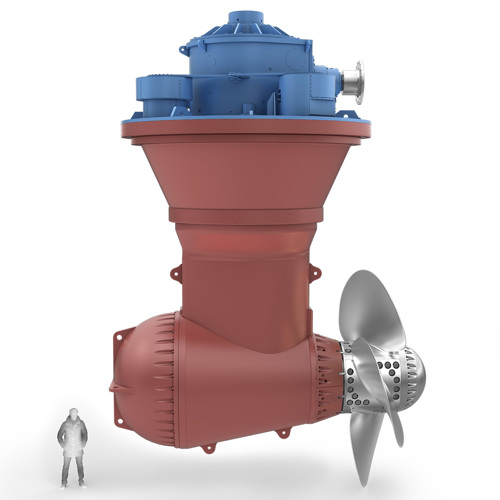

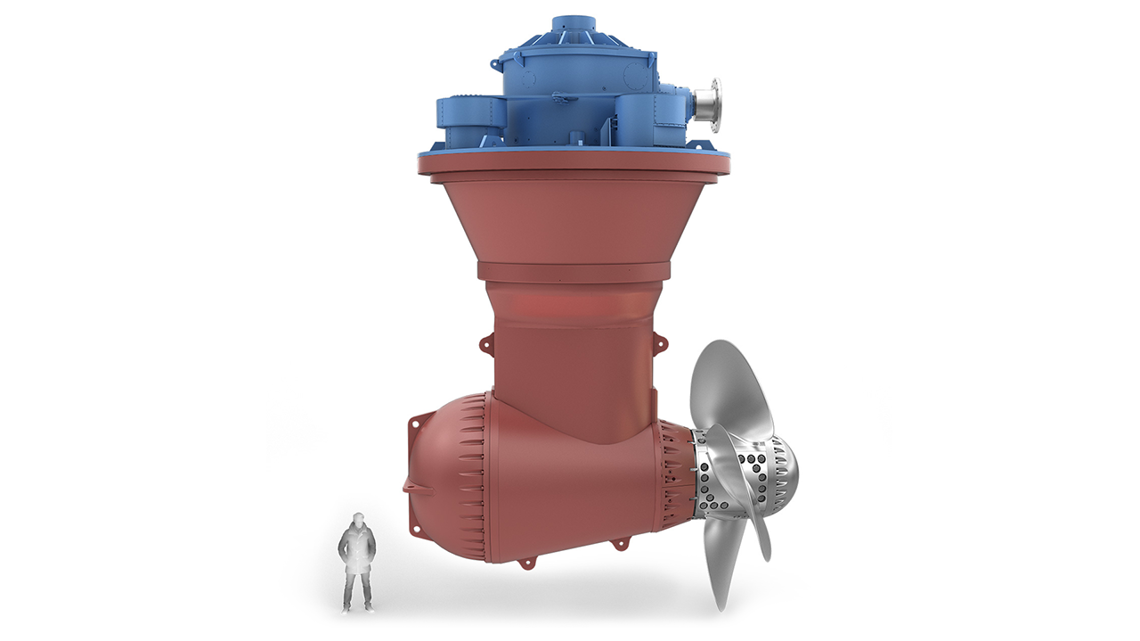

Arctic Thruster

Reliable thruster solutions for arctic ice conditions

Engineered for extreme environments, the Arctic thruster delivers robust performance and environmental compliance for ice-class vessels.

The Arctic Thruster (ARC) is a mechanical azimuthing thruster ideal for arctic ice conditions. Meeting Polar Class 2 and Icebreaker 7 standards up to 9 MW, the design has evolved through decades of experience and was updated in 2021 to comply with the latest industry requirements.

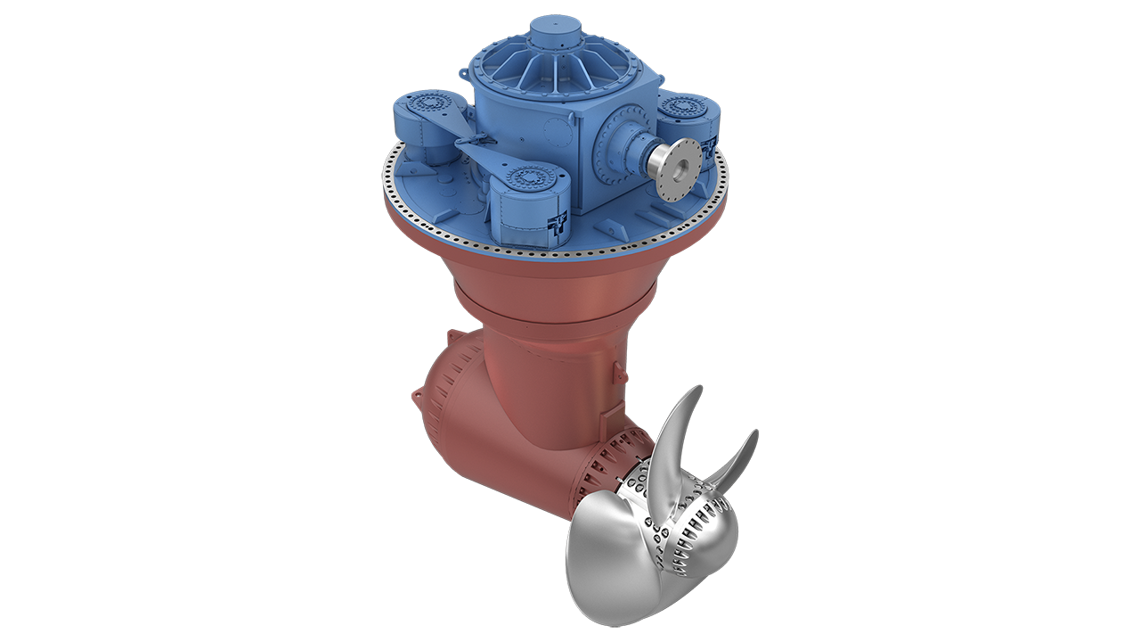

The ARC unit is available in both pulling and pushing versions

Ice milling with an open pushing propeller is done in reversed mode by using the propeller trailing edge. This is beneficial because the cutting is done by the sharp edge of the propeller and therefore the loads will be lower. In forward rotation mode the thruster leg protects the propeller from ice impacts.

ARC units with an open pulling propeller are typically more efficient when used in free running applications. Ice milling with a pulling propeller is done in ahead and astern direction cutting with the propeller leading edge, without the need to change the propeller rotation. When operating astern the unit is rotated through 180 degrees.

Nozzle

The ARC family is available with a ducted (with a nozzle) or an open propeller. The use of a nozzle will provide an increased amount of thrust at low speeds and bollard pull condition. The ducted ARC thruster is chosen when utmost thrust, and effective channel widening is needed.

When exceptional channel widening features are required an ARC unit can be equipped with a nozzle to enhance the thrust and let a traditional shaft line propeller function as the main propulsor. In that way it is possible to manage steering, channel widening and get an efficient forward thrust at the same time.

Zero emission sealing solutions

Kongsberg Maritime has spent several years developing zero‑emission sealing solutions and has built a dedicated test rig to meet increasing environmental requirements such as the Vessel General Permit (VGP). Extensive testing of various sealing concepts has been successfully completed and the solutions validated.

The new ARC thrusters have no oil‑to‑sea interfaces, and their outer dynamic seals include a monitoring cavity that can be inspected visually or automatically. Because these interfaces are eliminated, mineral oils can be used. The propeller shaft seal also features adaptive pressurization, ensuring optimal performance at any draught or speed and minimizing wear.

The propeller shaft uses an air seal, while the steering tube uses a void‑type seal. Both designs prevent oil discharge through two independent sealing systems - one facing oil, one facing water. Between them, an air chamber or void space forms a controlled buffer zone that collects any leakage and channels it to the thruster room, where it can be pumped to the ship’s waste tank.

Key Features:

- Available in pulling or pushing versions

- With open or ducted (nozzle) propellers

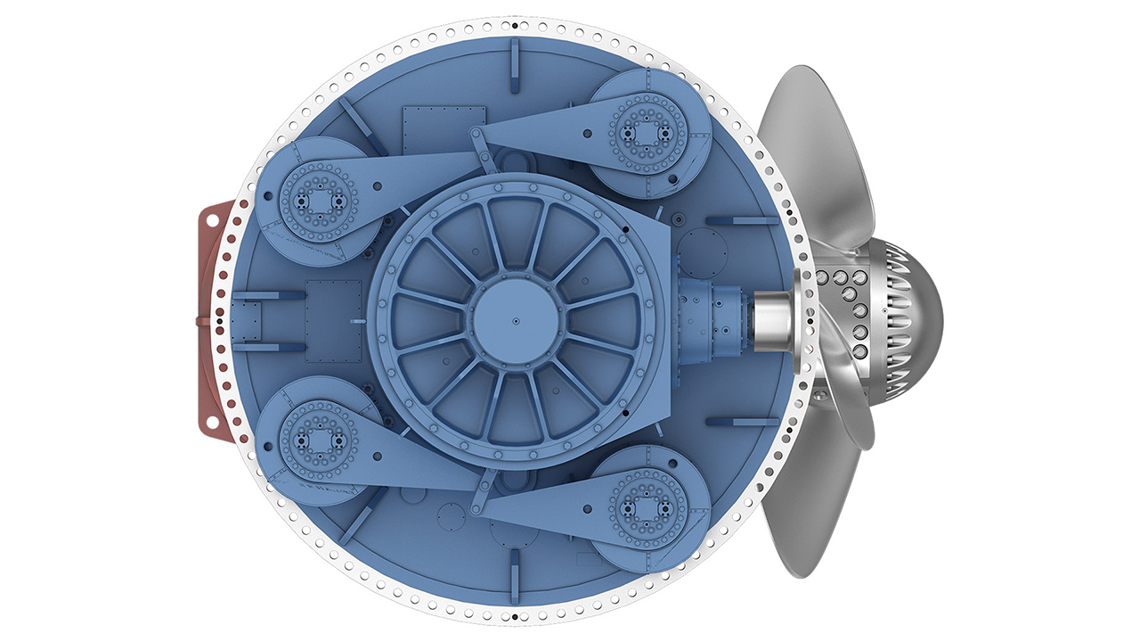

- Available in L - or Z-drive

- The L-drive delivers reliability, further optimised efficiency and compact footprint provided by a PM motor. Since the L-drive does not have an upper gear, it reduces the amount of underwater radiated noise (URN).

- Hydraulic steering gear

- FP propeller

- Various propeller sizes

- Variable speed electric drive

- Integrated condition monitoring system

- Environmentally friendly sealing solution

- Optimal for heavy ice conditions

Key advantages:

- Pushing propeller thruster arrangement, where ice breaking is done by gear housing instead of propeller

- Small lower gear housing is more resilient towards ice loads

- Reduced underwater radiated noise (URN)

- Ice-milling, a critical capability for overcoming ice ridges and complex navigation in heavy ice

TECHNICAL DATA

Ice Class Thruster Design

| ARC 0.5 | ARC 0.8 | ARC 1.0 | ARC 1.2 | |

| Input power range (KW) | 3000-4500 | 4500-6000 | 6000-7500 | 7500-9000 |

| Input speed (RPM) | 0-720 | 0-600 | 0-600 | 0-600 |

| Prop speed (RPM) | 0-173 | 0-143 | 0-143 | 0-135 |

| Prop dia. (m) | 3.2-3.8 | 3.8-4.1 | 4.1-4.5 | 4.5-4.8 |

| Dry weight (t) | 85-100 | 160-170 | 170-180 | 185-200 |

Get in touch with our experts

Arctic and multi-functional vessels require unique features. Kongsberg Maritime has the most comprehensive propulsion portfolio and decades of expertise and the ability to provide optimal solutions and combinations for arctic operations.

Lifecycle support for your vessel

-

24/7 Technical support

Get expert help anytime, anywhere—our global support team is available 24/7 to assist you.

-

Lifecycle enhancements

Upgrade your systems with tailored retrofit solutions to extend vessel life and boost performance.

-

Training

Explore our training programs to build skills, ensure safety, and maximize operational efficiency.