Promas with nozzle

Promas with nozzle

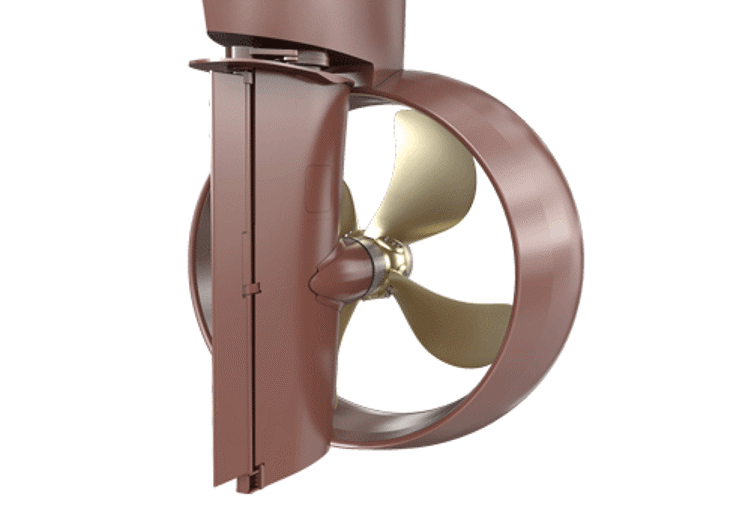

PROMAS with nozzle is the latest development for meeting various challenges on the market. The system is customised for the individual vessel and the shipping route to meet different ship profile requirements.

Superior design, BOLLARD PULL and fuel-saving capabilities

Promas with nozzle is a fuel-efficient solution that is robust and reliable with high bollard pull. The positive effects can be proven by extensive reference lists of various ship types and customers.

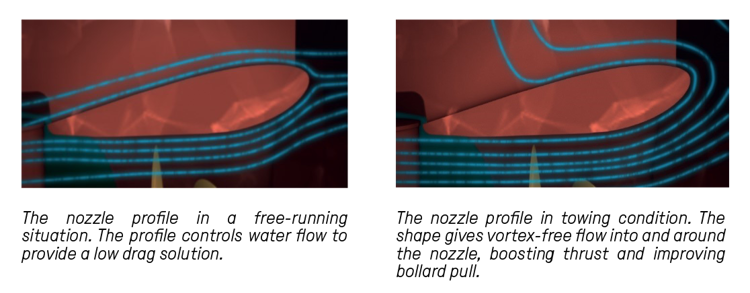

A natural evolution of the successful PROMAS system.The latest nozzle meets the highest requirements for pulling power at low speed at the same time with improved efficiency a high free-running speed in transit. Together with an optimised propeller, hubcap, rudder bulb, and a special rudder profile designed to work together in a ducted system. This maximises efficiency and minimising disturbances in the water flow both through and around the nozzle. The nozzle is a significant advancement in development on the profile used in conventional nozzle propeller installations. A typical anchor handler propulsion system will reduce fuel consumption in transit by 15-20% and improve bollard pull by around 5-8%. The rudder may be either a one-piece design or a medium flap-type, depending on the exact requirements of the operating profile.

The Nozzle Design

The PROMAS system gives additional positive effects. It optimises the hydrodynamic properties by reducing the creation of vortices, hub drag and the flow improvements allows for a more efficient blade design if done right. The rudder is twisted to reduce the risk of cavitation and increase propulsive efficiency and manoeuvrability. It is also possible to equip the rudder with a robust extension flap for improved low speed manoeuvering. The propeller can be manufactured and custom-designed with four- or five-bladed to fit the operational vessel profile. PROMAS with a nozzle is for vessels that need enhanced effects in thrust. In other words, ships that require high bollard pull such as anchor handlers, fishing, tugs and trawlers. Also, remarkable improvements of efficiency for dry cargo and bunker vessels with lower speed or ice-class.

Kongsberg Maritime has taken a natural step in research and development to meet increasingly strict regulations for the operation of marine devices. Additionally, our research centre and personnel ambitiously focus on essential research and developments for our customers. Specifically, we have noticed growing expectations in energy efficiency, quality and environmentally friendlier solutions. Shipowners, operators and shipyards are always interested in reducing fuel consumption, operating costs and installation time.

Key features

- Higher propulsive efficiency

- Increased bollard pull

- Proppeller, nozzle & rudder designed together as one unit

- High efficient innoduct nozzle profile

- Rudder with twisted leading edge and bulb

- Suitable for4 or 5 bladed propeller

- Easy adjustable hubcap length at installation

Key benefits

- Reduced fuel consumption 15-20%

- Increased bollard pull by 5-8%

- Optimised PROMAS system for specific ship types

- Short payback period

- Increased manoeuvrability

- Compact and robust design

- Designed to simplify and save time during installation

- Reduced noise and vibration of the system

- Reference lists available

- 24/7 Service and maintenance

Lifecycle support for your vessel

-

24/7 Technical support

Our 24/7 technical support team is there to help at any time, day or night, wherever your vessel is.

Our 24/7 technical support team is there to help at any time, day or night, wherever your vessel is.

-

Conversions, retrofit and refit

Upgrading and enhancing your vessel’s performance.

We understand the importance of having the right parts, available in the right place, at the right time.

-

Training

Maximise crew efficiency and reduce downtime with expert training.

Ensure that your crew is properly and thoroughly trained. This will reduce operational risk, downtime and maximise return on asset investment.