Heavy replenishment at sea (6te)

Heavy replenishment at sea (6te)

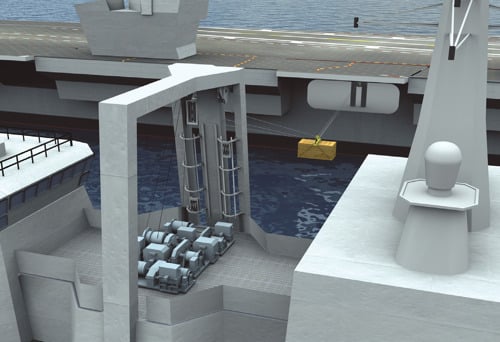

Kongsberg Maritime has developed and fully tested a heavy replenishment at sea (HRAS) delivery system. The all-electric HRAS replenishment system represents the next generation in abeam RAS technology and has been designed from the ground up for ease of use, maximum reliability, minimum through life cost, fast switch-on time and maximum availability.

The HRAS system was designed in order to provide dynamic load transfer capability for the future Solids Supply vessels. A prototype was constructed at HMS Raleigh Royal Naval Training Facility to derisk the design before full production took place.

The land based trials allowed critical assessment of the HRAS rig to test its dynamic response and load transfer stability in worst case sea state 5 conditions, even when at adverse vessel encounter headings. To our knowledge, no other high capacity replenishment at sea system has been dynamically tested and derisked to the same comprehensive extent worldwide.

Successful demonstration of the KONGSBERG Maritime HRAS system was concluded in September 2014 and it was deemed that the HRAS equipment met the advanced military equipment demonstration criteria of Technology Readiness Level (TRL) 6, which is defined as ‘successful demonstration in a representative environment’.

The HRAS system comprises of a single heavy Jackstay wire which is held in constant tension to support the weight of the load. The load rolls over the Jackstay wire running on a two sheave traveller assembly which is pulled in either direction by the Inhaul and Outhaul wires. The traveller assembly has been specially designed to keep the profile of the projecting steel wire ropes as low as possible when it enters the RAS reception area inside the receiving vessel RAS pocket. Mathematical simulation and land based trials were used to confirm the stability of the traveller assembly load while the vessels are subject to sea state 5 ship motion displacements, both as the load transits across the span and as it enters and exits the restricted space inside the hanger deck area.

The HRAS system can be configured as a dedicated heavy replenishment station for 6te supply or can be provided with selectable dual purpose solids mode to allow standard 2te capacity transfers to be conducted to other NATO vessels in addition to HRAS transfers.

Key features

- HRAS Delivery Systems

- 6te Solid supplies delivery equipment

- Up to Sea State 5

- 24 to 55m Operational Separation (can remain connected to 91m)

- All Electric Drives

- Automatic Transfer

- Low Through Life Cost

PRINCIPAL HRAS EQUIPMENT SPECIFICATIONS

Parameter |

Specification |

| Vessel speed range | 5 to 15 knots |

| Sea-state range | 0 to sea-state 5 (swh1 up to 5m) |

| Maximum vessel separation | 55m |

| Minimum vessel separation | 24m |

| Load mass range | 0 to 6,000kg (incl. stores skid mass) |

| Load max. dimensions | 5.6m x 2.6m x 2.6m (W x D x H) |

| Maximum load transfer rate | 25 transfers per hour |

| Climatic Environmental Conditions standard | Def-Stan 00-35 |

| Compliant Replenishment at sea equipment military standards | Def. Stan 07-279 STANAG 1310 ATP 16(D) |

| Electromagnetic compatibility specification | Def-Stan 49-511 |

| Nuclear / EMP hardening specification | Def-Stan 02-529 |

Lifecycle support for your vessel

-

24/7 Technical support

Our 24/7 technical support team is there to help at any time, day or night, wherever your vessel is.

Our 24/7 technical support team is there to help at any time, day or night, wherever your vessel is.

-

Conversions, retrofit and refit

Upgrading and enhancing your vessel’s performance.

We understand the importance of having the right parts, available in the right place, at the right time.

-

Training

Maximise crew efficiency and reduce downtime with expert training.

Ensure that your crew is properly and thoroughly trained. This will reduce operational risk, downtime and maximise return on asset investment.