MetaPower Quad

MetaPower Quad

Get complete data on shaft power and torque performance

One of the most challenging measurements to obtain on a ship are precise numbers on the torque transferred by a solid piece of shaft-steel over time. Our patented MetaPower Quad tool accurately provides this data – the key to many KPIs on engine and vessel performance, including EEXI and CII

A comprehensive measurement tool

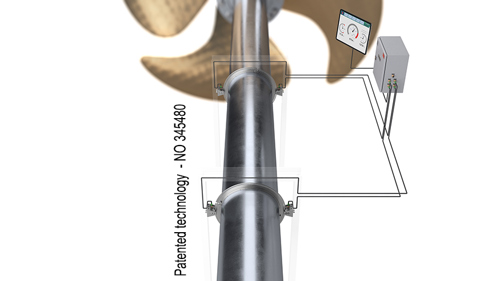

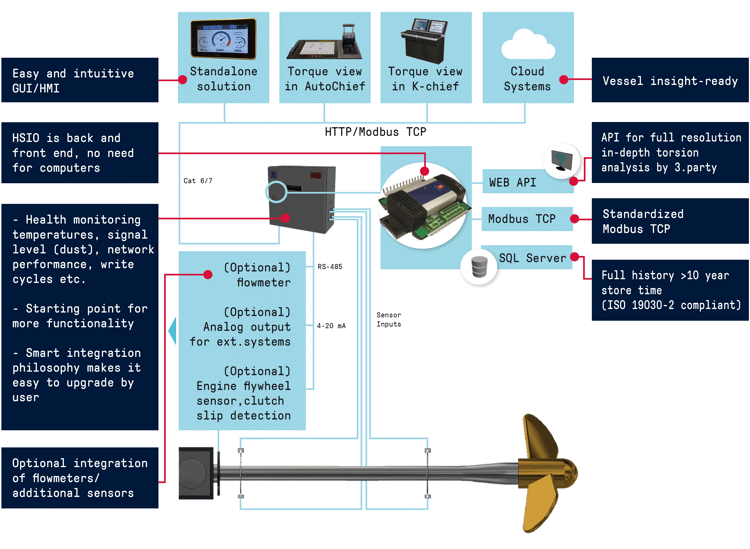

The MetaPower Quad is based on a patented design capable of measuring more than just shaft power. Two slotted wheels are installed with some distance between them on the shaft. Laser sensors individually read the wheels' relative position. Industry leading high-res processing of torque and power data is computed for every 1° of shaft revolution. Essential data are provided via TCP/IP for fast & lag-free communication. Also provides pre-processed data-sets for in-depth torsion analysis

Kongsberg Maritime has developed it's patented torquemeter over many years, with strong emphasize on long-term correct measurement, ease of use, and additional functions.

Obtaining data - Keeping data

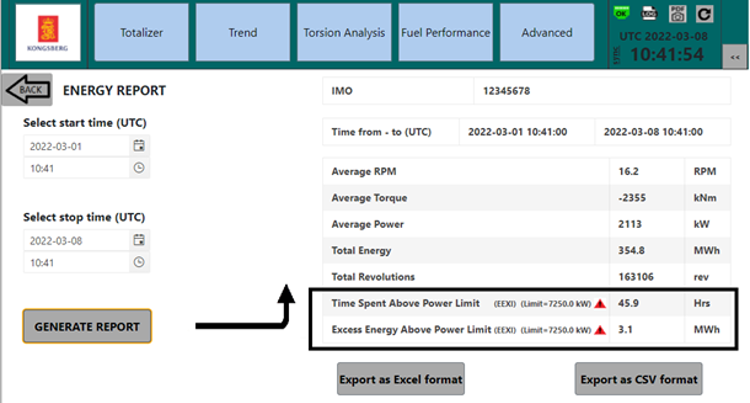

ISO 19030-2:2016(E) defines delivered power as one of two primary parameters for measuring changes in hull and propeller performance. The standard also specifies minimum data acquisition rates, which the data shall be recored with. For engine power this is 0.07Hz, or once every 15s.

MetaPower Quad has built in capacity to store such data for minimum 10 years. View the performance data in any relevant time perspective. The system is of course ready to share data. Connect to it with industry standard Modbus TCP, use the HTTPS interface or access the history database remotely with an SQL program.

Compliance with EEXI and CII regulations and Shaft Power Limitations (Shapoli)

Regulations were enacted in 2023 to reduce greenhouse gases from shipping. Shaft Power Limitation (Shapoli) is one of the methods to comply with these regulations.

Starting in 2Q/2022 MetaPower Quad is delivered with a functionality to set power limitation in accordance with EEXI regulation. This functionality will:

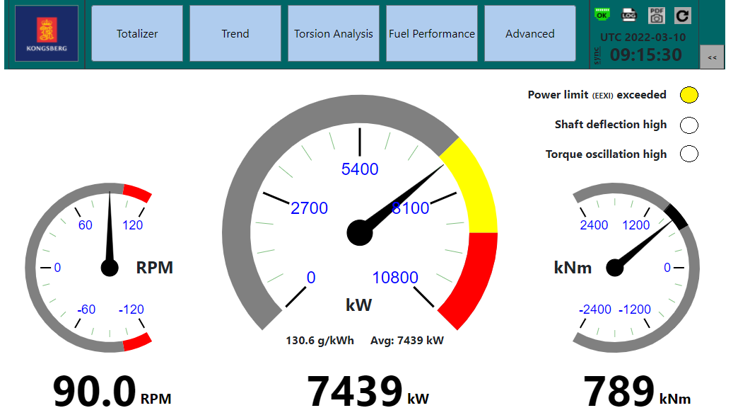

- Have clear visual indication of the limit on a gauge-scale

- Give a warning when the limit has been exceeded

- Log when, for how long and how much excess energy was consumed in case the limit is exceeded (NTP time-synchronization required for clock-verification)

- Log and keep track of the EEXI setting (tamper-proofing)

- Provide output to Engine Power Limiting systems (EPL), like the AutoChief governor system (AutoChief DGS C20/600 EPL)

Wee see four examples of ways to comply with the regulation:

- Physically limit the engine based on engine calculations, with mechanical sealings

- Digitally limit the engine based on engine calculations (AutoChief DC20/600)

- Digitally limit the engine based on shaft power measurement (MetaPower Quad, AutoChief DC20/600)

- Continuously log shaft power and EEXI limitations with an approved shaft power measurement system (Included with MetaPower Quad)

In combination with AutoChief C20/600 EPL you will get a system that measures the actual shaft power, and automatically limits the engine according to the measurements.

With only MetaPower Quad you will get a visualization and logging system that can help you to be compliant with the regulations.

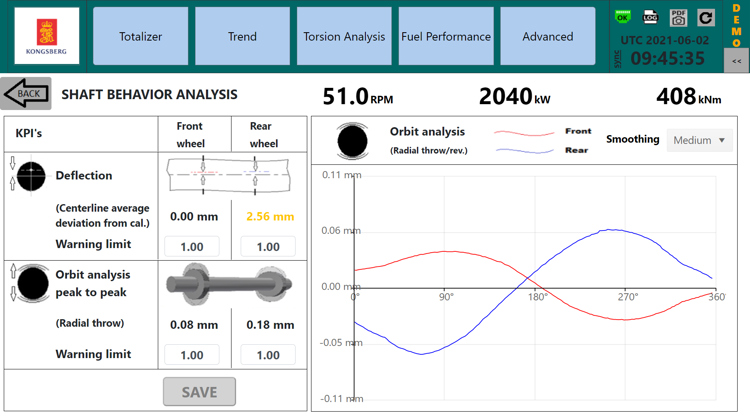

Shaft deflection (bending) and eccentricity detection

Using advanced algorithms, the quadrature arrayed sensors can detect deflection in the shaft, caused by bending forces and poor shaft alignment. The user will be alerted if the shaft is excessively bending or moving eccentrically throughout each revolution. The warning limits are adjustable to accommodate most installations.

Interactive demo of MetaPower Quad

OPTIONS

Flexible coupling monitoring (MetaPower Flex)

Kongsberg Maritime has successfully utilized the MetaPower measuring principle on ship engines with flexible couplings. This DNV class-compliant system gives the benefit of monitoring such couplings in real time with alarm functionality for critical conditions, as well as trending long term wear of the rubber material in the coupling. The system can measure angular twist, and twist amplitude in any coupling. Having this measurement may be required on some vessels. KM can provide a turn-key solution specifically for the type of coupling in question.

Read more in our data sheet for MetaPower Flex.

Clutch slip detection

By interfacing engine flywheel sensor (ME RPM sensor) to the shaft cabinet, the system will compare revolution speed between shaft and engine. Provided with the gear ratio, the system will alert immediately if the clutch is slipping.

Crank shaft monitoring

By interfacing encoder in front of engine to shaft cabinet, crank shaft monitoring is possible. Comparing encoder signal to front shaft code-wheel signal can provide insight on torsion and oscillations, isolated to the Main Engine crankshaft.

Fuel performance

By interfacing mass-flowmeters on fuel in and outlet, fuel performance option can be activated. Provides a very cost-effective, intuitive, standardized fuel calculation and logging system for single-acting main engines. Fuel and voyage data can be stored in the system up to 10 years. Use the report function or access the SQL data channel. The internal logging storage capacity is ~25 Gb, enough for most users.

Lifecycle support for your vessel

-

24/7 Technical support

Get expert help anytime, anywhere—our global support team is available 24/7 to assist you.

-

Lifecycle enhancements

Upgrade your systems with tailored retrofit solutions to extend vessel life and boost performance.

-

Training

Explore our training programs to build skills, ensure safety, and maximize operational efficiency.