Drilling unit

The world’s most experienced engineering partner for offshore drilling

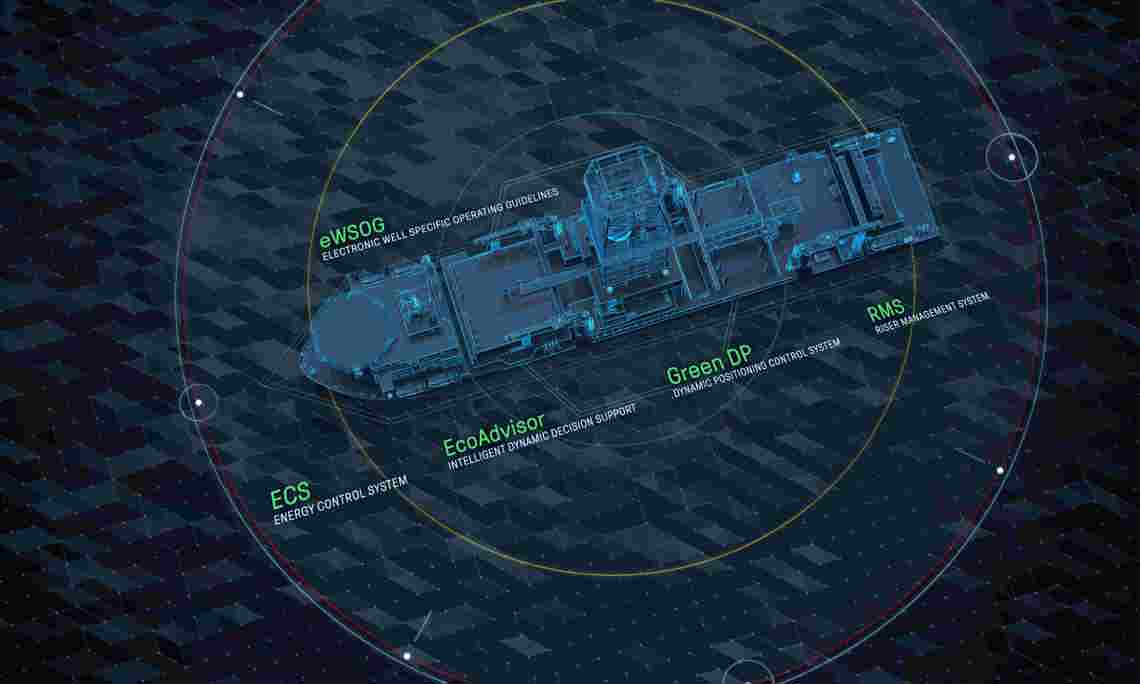

We are the world’s premiere supplier of integrated solutions for offshore drill units, including drill ships, semi-submersible drilling rigs, and jack-up drilling rigs. Our dynamic positioning systems are trusted by the world’s biggest offshore energy companies. We integrate state-of-the-art propulsion units, engines, deck machinery and control and safety systems, along with riser management and BOP technology to reduce costs over a drill unit’s lifecycle.

Powering performance with proven advantages:

- K-Pos dynamic positioning trusted by world’s largest offshore drillers

- Robust safety systems

- Full lifecycle support for drill ships, drilling semi-submersibles and jack ups

- Decades of experience and data in the offshore oil and gas industry

Modern drilling units are defined both by their increasing complexity and a need to perform with optimal efficiency and sustainability, often in extreme environmental conditions. KONGSBERG addresses these challenges through smart, future-proof integration between all systems onboard, robust system design and efficiencies that both reduce cost and enhance performance.

KONGSBERG solutions for drilling operations are designed to improve the performance of a drilling unit, empowering you to increase efficiency, lower costs, improve safety and lessen the environmental footprint of energy E&P. Additionally, deeper integration of diverse equipment and technologies unlocks the potential for reduced time for installation, commissioning and testing, brining significant efficiencies to the engineering stage of your asset.

The unique integration of state-of-the-art propulsion units, engines, deck machinery and control and safety systems, along with proven riser management and BOP technology from a single highly experienced supplier can reduce cost elements for a drilling unit throughout the entire lifecycle.

- Ship designers can tailor their solutions for specific operational requirements together with KONGSBERG. Seamless integration can free up space and reduce weight, allowing for smarter, more efficient drilling unit designs.

- The shipyard can enjoy a lower risk profile for the project, save engineering hours with significantly reduced cabling and installation work, as well as reduce hundreds of hours spent on interface meetings in the early stages.

- The owner and operators can reduce OPEX by establishing more efficient drilling operations. A proven life cycle management system for the delivered solution can, in the long run, lower costs and increase the uptime of your asset.

Reducing energy use during offshore drilling

Our proven solutions in power management for offshore can yield big savings for drill ship and drill unit operators