New product!

We have just added this product to our product portfolio.

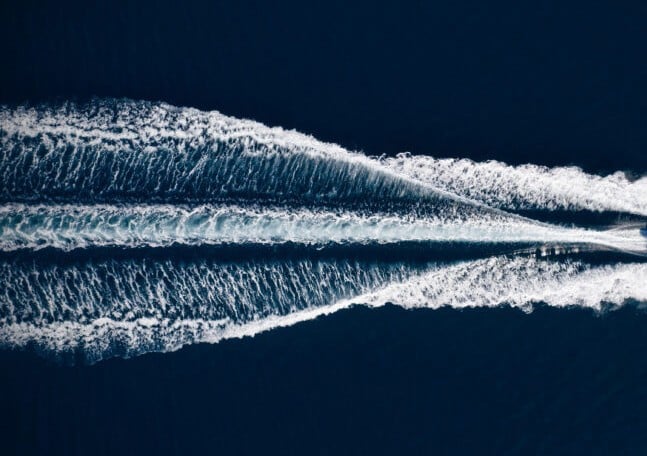

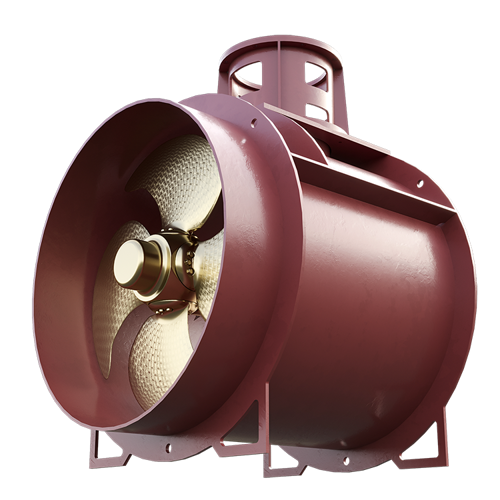

Power and precision from a new generation of Tunnel Thrusters

Performance and design flexibility, engineered for various marine applicationsTunnel Thruster type TTH

The TTH Tunnel Thruster represents the next generation of our proven tunnel thruster technology.

Backed by over 60 years of hydrodynamic expertise, the Harmonised (H) range is designed to deliver compact, flexible, and installation-friendly propulsion performance for vessels operating in complex environments — from offshore platforms to naval operations.

Available in two propeller diameters — 1650mm and 1850mm — with power up to 1250kW, the TTH is optimised for Dynamic Positioning (DP) and Auxiliary (Aux) propulsion applications.

Performance benefits

-

Flexible configuration to meet varying operational profiles

Flexible configuration to meet varying operational profiles

-

Hydrodynamically optimised blade designs for high efficiency and thrust

Hydrodynamically optimised blade designs for high efficiency and thrust

-

The enhanced design enables lower noise and vibration levels

The enhanced design enables lower noise and vibration levels

-

Fully compatible with Environmentally Acceptable Lubricants (EALs)

Fully compatible with Environmentally Acceptable Lubricants (EALs)

Technical data

| Thruster Type | Propeller Diameter (mm) | Propeller Type | Max Power (kW |

| TTH | 1650 | CP / FP | 1091 |

| TTH | 1850 | CP / FP | 1250 |

Lifecycle support for your vessel

-

24/7 Technical support

Our 24/7 technical support team is there to help at any time, day or night, wherever your vessel is.

Our 24/7 technical support team is there to help at any time, day or night, wherever your vessel is.

-

Conversions, retrofit and refit

Upgrading and enhancing your vessel’s performance.

We understand the importance of having the right parts, available in the right place, at the right time.

-

Training

Maximise crew efficiency and reduce downtime with expert training.

Ensure that your crew is properly and thoroughly trained. This will reduce operational risk, downtime and maximise return on asset investment.