- cNODE IQAM launches at Ocean Business 2017 – stands N1 & P2

- Provides dual usage for positioning during subsea installations and life-cycle monitoring

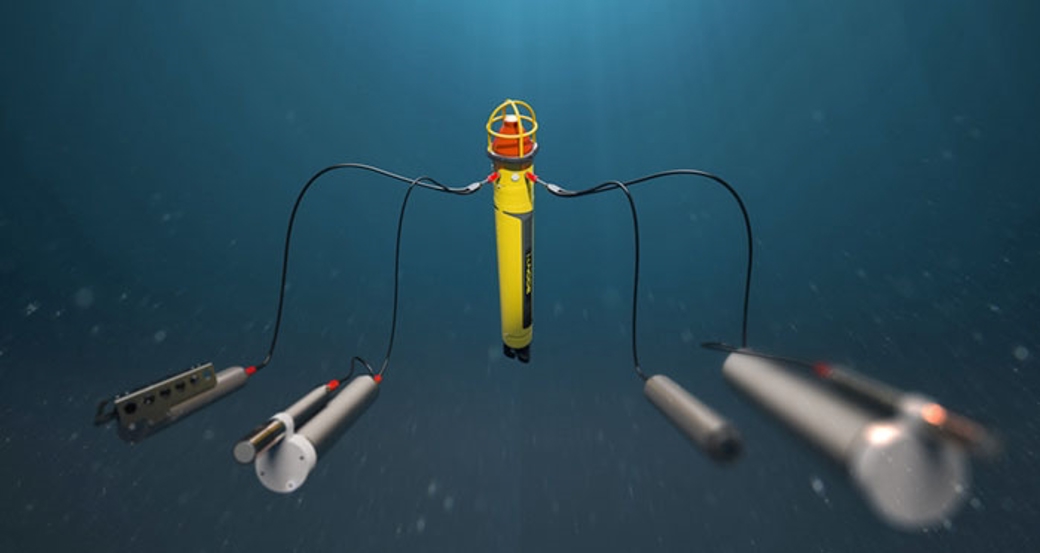

cNODE IQAM (Intelligent Data Analysis and Monitoring) is an advanced instrument system developed for a broad range of subsea data acquisition and integrity monitoring applications for seabed structures, including anchor piles, manifolds, PLETS, well heads and pipelines. It can also be used for general environmental, leak detection, seabed deformation or subsidence monitoring.

Data outputs from cNODE IQAM's range of internal or external sensors are logged and processed with onboard data analysis algorithms to provide the key events operators require. The intelligent data acquisition processor on board the cNODE IQAM is capable of running custom algorithms or standard event analysis based on simple statistics of min/max and mean, with set values used to trigger alarms.

Internal sensor modules are available for cNODE IQAM to measure inclination, acceleration, pressure and sound velocity. External sensors that can be seamlessly interfaced include Kongsberg Maritime's Contros Co2, CH4 and O2 sensors, ADCPs, pressure sensors, inclinometers and current meters. More sensors can be added according to customer requirements.

cNODE IQAM benefits the entire subsea construction value chain. It has the flexibility to operate as a standard cNODE transponder for LBL and SSBL position, allowing a seamless transition from subsea installation and commissioning through to long-term monitoring duties. Dual usage in this way negates the need for operators to source and install a separate, standalone monitoring system, reducing through-life project costs.

Data is transmitted using robust Cymbal acoustic protocols to cNODE Modems or any modern portable, or vessel-installed KONGSBERG HiPAP SSBL system. Cymbal is Kongsberg Maritime's proprietary digital telemetry solution, offering numerous protocols to ensure the robustness of data transfer depending upon the environment. cNODE IQAM can operate with both internal and external batteries and features low power electronics and configurable sensor logging intervals to maximise subsea deployment time.

cNODE IQAM can be built from a range of materials including hard anodised aluminium through to super duplex stainless steel for corrosion resistance. It is available in two sizes using standard cNODE Maxi and cNODE Midi housing designs, depending on battery requirements.

"While expanding the capabilities of the established cNODE range, cNODE IQAM also builds upon our existing subsea monitoring portfolio," said Spencer Collins, Sales Director UPM, Kongsberg Maritime. "cNODE IQAM's dual usage, where it can provide highly accurate positioning at the installation phase, then left in place to provide on-going monitoring during commissioning offers a flexible approach that can help reduce costs and simplify planning for any subsea construction and monitoring project."