- Live trials of a new solution to combat biofouling on essential underwater fish farm sensors taking place in Norway

- Extending time between sensor head cleaning from one month to 18 months

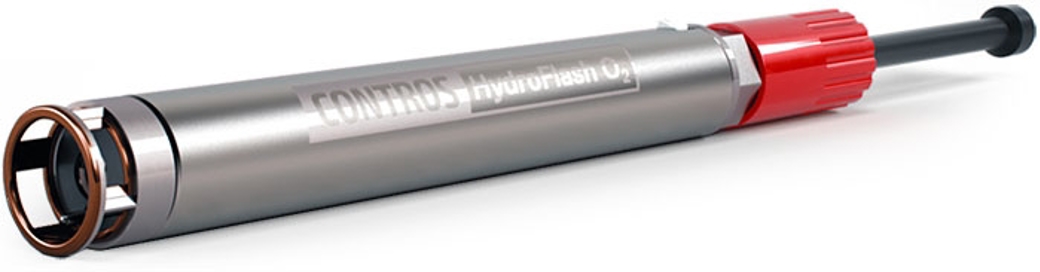

The trial, taking place in Norway, is based on deployment of KONGSBERG's CONTROS HydroFlash O2 subsea oxygen sensor. The sensors have been installed with the AML Oceanographic Biofouling Control system, which can enable them to remain in place without cleaning for up to 18 months. Currently, subsea fish farm sensors require cleaning approximately once a month, to ensure continuous operation. AML's biofouling technology is a more economic and environmentally friendly alternative to the present practice of injecting poison into the environment to protect the instrumentation.

Biofouling is a common and costly problem for fish farms. Fouling prevents accurate readings from sensors, necessitating frequent maintenance. The AML Oceanographic Biofouling Control system integrated on KONGSBERG's sensors for the trial uses UV light to prevent the formation of biofilms on surfaces. If the biofilm is prevented, biofouling will not occur on the surface. The premise has been known since the 1950's however practical implementations have not been possible until now. AML Oceanographic's UV biofouling systems combine low power, flexible irradiation areas and compact size into a device well suited to protecting oceanographic instrumentation.

The weather plays an important role in fish farm sensor maintenance, with harsh winters making it more difficult to ensure cleaning can be carried out regularly. This problem is further compounded for the new ‘exposed' Ocean Farming As/Salmar fish farm development taking place offshore Frohavet in Norway. Due to the exposed nature of this, the world's first offshore fish farm, sensor maintenance will become more difficult so a solution that enables longer sensor deployment without the need for monthly cleaning is an important cost and efficiency factor. KONGSBERG is a key technology stakeholder in the Salmar exposed fish farm development, having been contracted to deliver subsea, surface and vessel systems

CONTROS HydroFlash O2 subsea oxygen sensors are a versatile subsea, shallow and deep-water oxygen sensor used for autonomous deployments as well as integrated into sensor systems, including KONGSBERG's K-Observer autonomous monitoring, analysis and reporting system. The advanced, optical sensor is based on the principle of fluorescence quenching. Due to the chemical interactions required to make the sensor work, keeping the sensor surface clear of biofouling is essential.

"If it is possible to use Oxygen sensors for one full breeding cycle, and only clean them during the service period between, the fish farming industry will see benefits in both reduced operational costs and increased safety," said Sören Themann, VP Subsea Monitoring, Kongsberg Maritime. "The unique combination of the CONTROS HydroFlash O2 subsea oxygen sensors and AML's anti-fouling capabilities has already proven to be a very good fit. The trial so far has delivered promising results. The system is deployed at a real fish farm in Norway and will stay there for a full year. After the first three months no biofouling has been found in the sensor area."