ELECTRIC DIRECT DRIVE THRUSTERS

Kongsberg Maritime, as an early adopter and advocate of electric direct drive thruster technologies, is set to maintain its pole position as the world leader in this increasingly important growth area of electric propulsion.

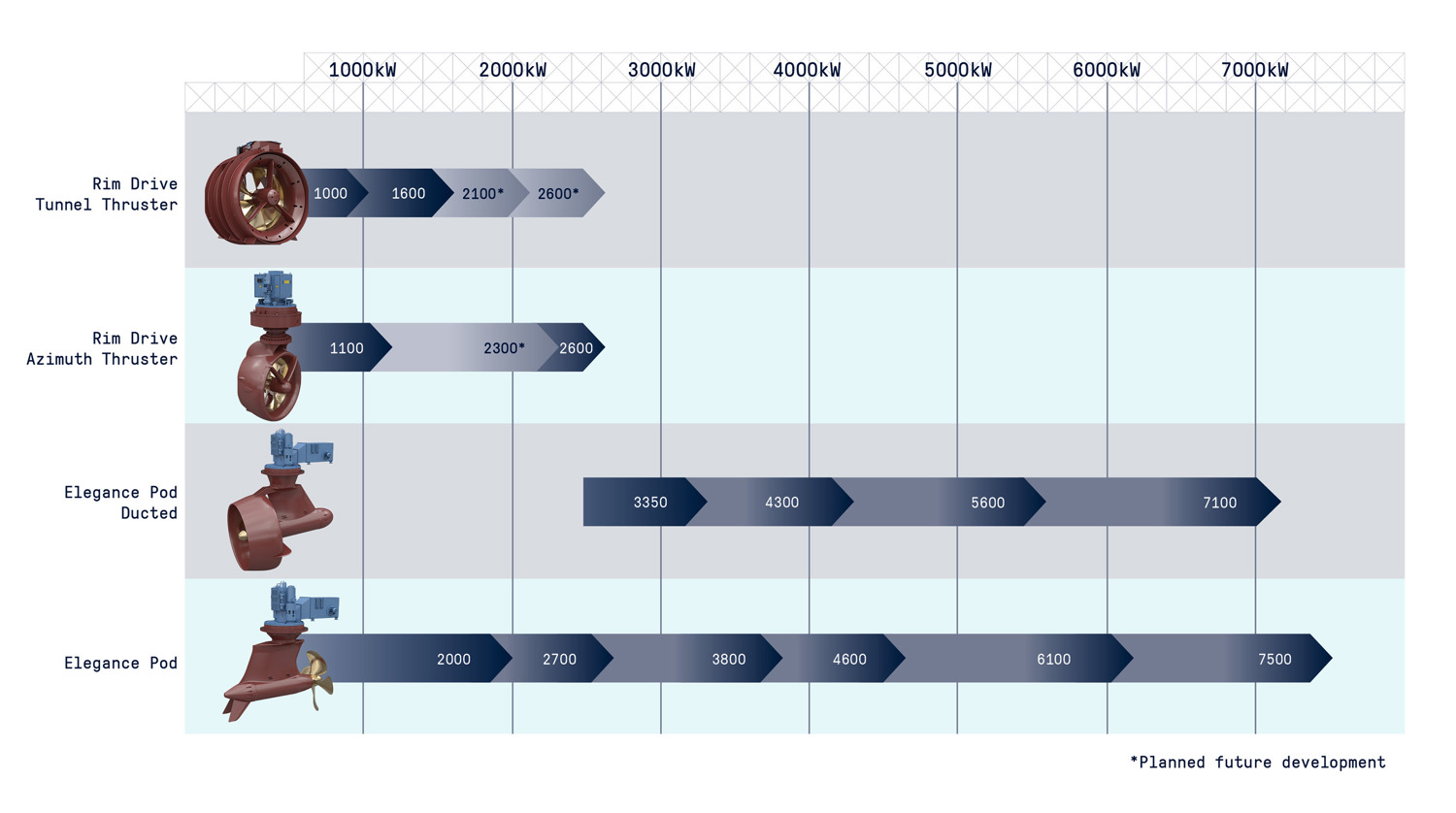

Following a development journey over three decades of constant improvement, KONGSBERG is pleased to offer the broadest portfolio of electric propulsion solutions in the market today. All are driven by the latest generation of compact, power-saving permanent Magnet motors.

KONGSBERG DIRECT ELECTRIC DRIVE THRUSTERS RANGE OVERVIEW

LONG JOURNEY OF SUCCESSFUL ELECTRIFICATION

The development journey began with pioneering work on the then forward-thinking podded propulsion systems that were emerging in the first part of 1990s. The result was taken to the market in 1998 when the first pods were launched. These 7-22MW pods were successfully installed across several market segments from offshore applications to naval vessels and large cruise ships and have accumulated more than five million operational hours.

KONGSBERG continued the focus towards sustainable solutions and began development of rim driven thrusters based on permanent magnet motor technology in the early 2000s. The first units, in the form of tunnel thrusters, were installed on a vessel in 2005.

FUNDAMENTAL ADVANTAGES

Fully electric azimuthing propulsors, where the motor is mounted directly to the propeller or propeller shaft inside the rotatable thruster unit, have a number of distinct advantages over more traditional shaft, gearbox, rudder and propeller systems. With the motor coupled directly to the propeller, the losses in the driveline are reduced to a minimum, and the thruster unit is rotatable 360 degrees which allows fantastic vessel manoeuvrability.

As the motor and shaft line are fitted outside the hull, noise and vibrations experienced within the vessel are much lower. This also provides a good opportunity to bring down fuel burn and operational cost, reduce noise pollution as well as being able to minimize turn-around times in ports and manoeuvre in narrow harbours and straits. Because of these features, early adopters were mainly within the cruise, research, and naval sectors, where manoeuvrability and low noise are highly valued.

“It has been an exciting journey, helping electrify the marine market. In the 90s we saw the change in the market, in particularly in the cruise segment, moving into electric propulsion. With our experience from the rotating thrusters, we identified the benefits that could be achieved from direct drive propulsion, cutting away all the gear losses in a conventional drive train, in combination with the manoeuvrability achieved from the azimuthing units”.Per Nahnfeldt, Product manager for electric thruster propulsion

SET FOR SUCCESS

Testing and validation is essential to ensure that the technology is mature when taken to market. A dedicated test rig is situated at the quayside near the assembly line in Ulsteinvik. Over the last decade several thousand hours of tests have been run to trial and fine tune the technology. This is of course a very valuable tool, for the development process, as there are so many things that need to be understood in new products. Tools like these are key to trialling propulsion systems in a safe and proactive manner.

To be able to meet the growing market demand for Electric propulsion, KONGSBERG is investing not only in technology, but also in the capability to deliver it efficiently. A top modern assembly plant was built in Rauma a few years back where a new production line is in place, producing the Elegance pods. Here efficient tools and production methods allow for an effective production that can provide the highest quality standards.

At Ulsteinvik, work is in full swing to upgrade the factory for a customised rim drive thruster assembly line. The old machine shop has been torn out to make room for a top modern assembly plant for the rim driven thrusters. This provides the right platform to produce efficiently the quality that the market has come to expect from Kongsberg Maritime.

“We are committed to our product and technology developments, and we continue the work of sustainable solutions meeting our customer’s needs. Utilizing and continuing to grow our superior knowledge, skills and facilities will ensure that our electric thrusters are the best performing electrical thrusters in the market”.Hildegunn McLernon, SVP Technology, Propulsion & Engines

Kongsberg Maritime also has a long history of providing silent propellers. This builds on more than 50 years of testing in the cavitation tunnels at the in-house hydrodynamic research center. The in-house team of naval architects and hydrodynamic specialists are essential to ensure optimized performance with high efficiency together with low noise and vibrations.

“We started building our own CFD (Computational Fluid Dynamics) capability in the 1990s. The strength from being able to combine these two fields of calculation and validation testing, gives us a unique capability to optimize the performance to meet tough requirements from our high-end customers” says Göran Grunditz, Manager Hydrodynamics. “We have fine-tuned our calculation and testing tools through a large number of full-scale measurements to verify our results. This gives us the power to predict performance accurately.”

To make sure the system leverages the full benefit of the thruster technology, Kongsberg Maritime offers integrated solutions covering everything from the bridge to the propeller. This includes high end energy management systems, advanced manoeuvring solutions and automated support systems, so that all vessel operations can be safer, more closely managed and burn less fuel. The underwater radiated noise will also be reduced through well-tuned frequency drives connected to the permanent magnet motors.

GROWING DEMAND

There is a growing demand for electric propulsion, and it is expected to accelerate as part of the green transition of the maritime industry. Traditionally, the cruise, superyacht and naval segments were leveraging the benefits of silent and efficient propulsion. Now the fast-growing renewable industry, such as the offshore wind installation, operation and maintenance vessels, are showing increasing interest in electric propulsion. Kongsberg Maritime’s Rim drive thrusters have proven to be a good match for this growing business.

“We are investing in state-of-the-art technology from KONGSBERG. Our operating cost will be significantly reduced compared to the use of conventional thrusters, and the same applies to our environmental footprint. This gives us vessels designed for the future in advanced marine operations in the offshore wind market.”Svein Leon Aure, CEO of Norwind Offshore

Underlining KONGSBERG’s extensive work in driving the electrification of the Marine market, the company recently received, for the second time in three years, the Manufacturer of the Year Award at the highly regarded Electric & Hybrid Marine Awards 2022 in Amsterdam. A very positive statement showing how KONGSBERG is taking a leading position in innovation and services to enable cleaner, more efficient and more sustainable marine operations.