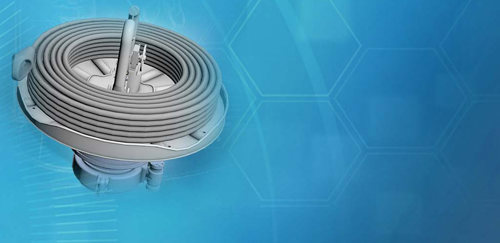

Pennant winder and spooling sheave for anchor handling vessel

Designed with safety in mind to uncoil pennant wires and to safely spool them up again into manageable coils after use.

Design to make deck operations safer

The pennant winder is designed to uncoil pennant wire coils and spool the wire up again into manageable coils again after use. It handles up to 200 metres of 84 mm wire weighing up to 6 tonnes.

It comprises two main parts, the detachable rotating platform with coil control arms on deck, whose shaft engages the socket of the low pressure hydraulic drive motor which is located under the deck. After use the coil winder can be removed and stored until needed again. The operator can stand inside the cargo rail in a protected place, using the control panel which allows the tension to be adjusted for spooling off or on.

The spooling sheave, a 1,500mm diameter freely rotating sheave, is easily fitted on to the raised shark jaw, and is typically used in conjunction with the pennant winder to guide the wire to and from the winch.

Lifecycle support for your vessel

-

24/7 Technical support

Get expert help anytime, anywhere—our global support team is available 24/7 to assist you.

-

Lifecycle enhancements

Upgrade your systems with tailored retrofit solutions to extend vessel life and boost performance.

-

Training

Explore our training programs to build skills, ensure safety, and maximize operational efficiency.