SAVe energy, SAVe fuel, SAVe costs

KONGSBERG INTEGRATED HYBRID POWER PROPULSION SYSTEM – THE FULL PICTURE

Kongsberg Maritime’s hybrid propulsion system has been proven to offer significant efficiency benefits across a range of ship types, with the technology now widely considered as the key to meeting the IMO’s carbon reduction strategies.

Typically, a Kongsberg Maritime hybrid system can be expected to offer fuel efficiency gains of around 20%, with corresponding reductions in emissions.

SAVe Energy

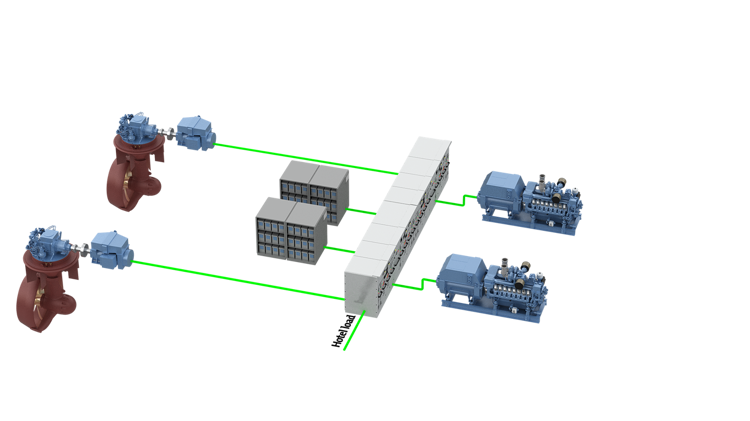

At the heart of the hybrid package is the SAVe Energy storage system, based on cost-competitive, high-efficiency, liquid-cooled, lithium-ion battery modules, dimensioned for each particular vessel, and including intelligent power control.

In applications where battery-powered vessels can be applied, a SAVe battery system can provide the sole power source. In other applications, it can be combined with diesel or LNG-fuelled engines to achieve increased efficiency and lower emissions. Even a small battery installation – such as that provided by KONGSBERG’s SAVe Cube – will provide load smoothing and improve operating conditions for the engines.

SAVe Cube

The latest generation SAVEe Cube system is designed with a single integrated drive switchboard for the whole vessel. All frequency converters, drives and switchboards are housed in a single cabinet for a significantly smaller footprint. A single cabinet is simpler to cool and has fewer connections. Extra battery power is available for slow speed transits in harbour or for peak power load smoothing, while all engines can operate at variable speeds to maximise their efficiency for the required power.

This system is an ideal solution for platform supply, multi-purpose, emergency response/rescue, coastguard and research vessel, since engine speed is adjusted automatically to suit the power demand in the most fuel-efficient way.

A typical hybrid system is a combination of diesel or LNG-powered generators and batteries. In a standard system, the battery power tends to be used to take off or shave peaks, which can be wasteful and less efficient. Kongsberg Maritime’s solution is to apply Dynamic Inertia Control, which carefully balances the power usage between all components, ensuring generators are operated at maximum fuel efficiency.

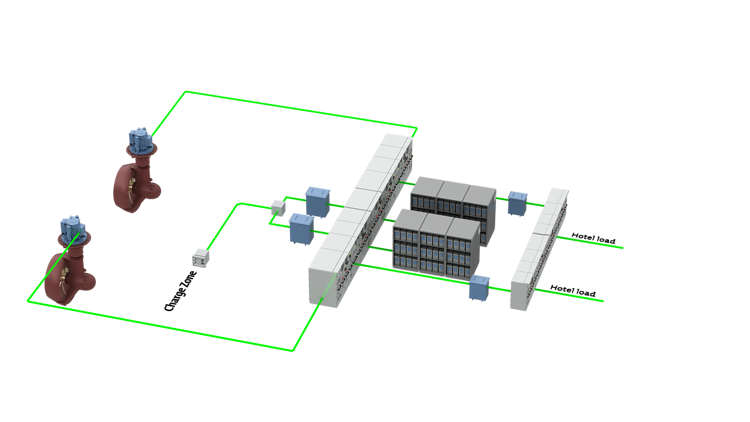

SAVe Charge

At the same time, it controls the charging rate for the batteries, optimising both efficiency and battery lifetime.

Systems can be optimised for diesel/gas hybrid or plug-in hybrid applications; in the latter, shore power is used for charging while the vessel is docked.

This allows more use to be made of the stored battery energy, with smaller onboard generators installed. The SAVe Charge plug-in hybrid solution ensures intelligent and efficient charging.

Achieving that optimum balance between generator and battery power is vital, and in KONGSBERG’s case the solution is the company’s Power and Test Lab.

This allows an entire system to be simulated on real hardware prior to delivery and installation, saving on commissioning and troubleshooting.

Another aspect of the company’s research into battery applications has been the use of a containerised battery pack, which can be moved between ships to suit various requirements.

Energy Management

All of the technologies that form part of a Kongsberg hybrid propulsion system can be integrated with the company’s state-of-the-art Energy Management system, enabling further reductions in fuel consumption and operating costs.

Energy Management 2.0 offers a greatly enhanced ability to improve the performance of an individual vessel or a fleet. The system provides details on fuel consumption and overall energy efficiency levels benchmarked against historical performance, allowing the crew to exploit opportunities to minimise fuel usage and reduce emissions.

Data is collected from the ship’s control system and a multitude of sensors on the vessel, logged at frequent intervals and processed in real time. Data sources include the engines, propulsion system, automation system, deck machinery and other equipment. Selected information is displayed graphically using a clear, focused and uncluttered design that draws the crew’s attention immediately to key elements.

By moving to a Kongsberg hybrid or electric propulsion, owners have in-built flexibility that not only provides an unsurpassed level of operational redundancy, by reduces emissions and fuel consumption, is lighter, taking up less space, and is less costly to maintain.