Propulsion for the new age of navies

Expanding mission profiles and a growing demand for flexibility are driving creativity in propulsion solutions that combine speed, power, silence and manoeuvrability.

-

Craig TaylorSenior Manager PR & Communications

“The combination of propellers and waterjets is quite a challenge to design,” says Göran Grunditz, Kongsberg Maritime’s Director of Hydrodynamics.

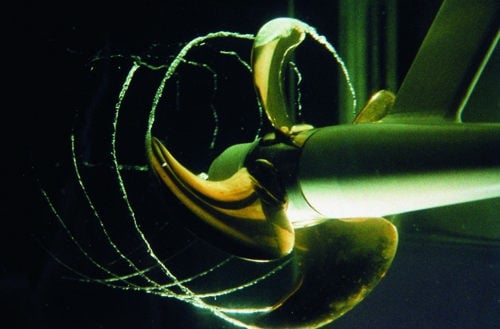

Though simple in theory, making all the parts work together efficiently requires considerable testing and refinement. Göran points to the difficulty of getting a pair of CPPs to adjust to the high speeds generated by the waterjet without causing undue noise or resistance. “To maintain the power of the propellers, we need to increase the pitch of the blades quite significantly and keep increasing the pitch as the speed increases. That is a unique operating condition,” he says.

Göran and his team at the company’s Hydrodynamic Research Centre (HRC) in Kristinehamn, Sweden, are fine-tuning the details on the underwater profile of a new vessel equipped with a waterjet-CPP combined propulsion system. Working with CFD (computational fluid dynamics) software, the HRC is creating models that can be tested in dedicated tunnels then further refined beyond what even the latest software can achieve. “We are testing some alternative design features like super-cavitating profile shapes,” says Göran. “It’s about building new capabilities and pushing the limits. From our perspective, this is the type of product we want to see, because we learn a lot.”

Nils Waltré, Kongsberg Discovery Sales Manager, is a former submarine officer and sea captain. He reckons that geopolitical shifts and crewing pressures have supercharged the need for unmanned solutions. “The number of sailors in the world is declining rapidly but the demand for ocean-going vessels is going up, so everything is going in this direction,” he says.

Nils and Kongsberg Maritime engineers are working on vessel concepts for USV deployment that will rely on a combination of waterjets and electric pods.

Such vessels would use waterjets powered by diesel engines to get to an operational zone quickly then switch to electrically powered rim drives to reduce underwater noise and allow for the relay of survey information and commands with the mother ship.

A key design challenge will be getting all the elements, including the different propulsion systems and positioning sensors, to talk to each other for easy control and responsiveness.

Pods have the power

One possible outcome of the increased focus on unmanned aerial vehicles (UAVs) and USVs in the naval sector is a proliferation of small carrier vessels designed to host and deploy unmanned craft or even a squadron of helicopters. Such carriers would rely on podded propulsion and dynamic positioning for stability in flight operations, rather than size and bulk. Patrik Kron (left), Kongsberg Maritime’s Chief of Naval Systems, points to the French Navy’s Mistral-class of carriers, which combined small-scale helicopter and amphibious operations, as a glimpse into the future.

“They [the Mistral class] projected a development which could take a decade or more for some big navies to pick up, but other navies not linked to that tradition [of large-scale carrier operations] might do,” Patrik says.

He adds that South Korea is a good example of an innovative country that takes the best technology available now to start creating such solutions. Though Patrik is reluctant to call smaller, multi-purpose carriers a trend, he admits that more questions are being asked about the possibilities of such carriers, rather than large carriers that require a small navy just to protect and support it.