Preparing the LNG workforce for a cleaner future

As the maritime industry shifts towards cleaner energy, LNG is becoming a key fuel choice - especially with stricter sulfur emission regulations. However, with new fuel sources come new challenges, requiring specialised training for safe and efficient operations.

-

Text:Article first published in LNG Industry Aug 2025

Photo:Kongsberg Maritime

The introduction of the 2020 International Maritime Organization (IMO) sulfur cap, which limits sulfur content in marine fuel to 0.5%, is a defining moment that has already triggered a significant shift towards LNG-fuelled vessels. This move is particularly impactful in Emission Control Areas (ECAs), where stricter local standards apply.

Transitioning to LNG is not just about retrofitting engines or building new dual-fuel ships; it is about people. The safe operation of LNG-fuelled systems on board vessels requires advanced training and deep operational understanding.

This article takes an in-depth look at technology such as the K-Sim® Engine LNG Bunkering solution, exploring their regulatory basis, technological capabilities, and training modules, as well as how they are delivering transformative results in real-world maritime education settings, preparing the LNG workforce for a cleaner future

Understanding the regulator landscape

The 2017 introduction of the IMO’s International Code of Safety for Ships Using Gases or Other Low-flashpoint Fuels (IGF Code) marked a pivotal step in regulating the safe use of LNG and other low-flashpoint fuels in marine vessels. Following closely, the Standards of Training, Certification, and Watchkeeping for Seafarers (STCW) were updated to include specific LNG-related competencies.

Section A-V/3 of the STCW Code now mandates:

- Paragraph 1: Basic training for all personnel responsible for designated safety duties related to LNG fuel handling and emergency response.

- Paragraph 2: Advanced training for masters, engineer officers, and those with direct responsibility over LNG fuel systems.

For maritime training institutions and ship operators, these new directives create a pressing need to equip crews with not only theoretical knowledge but also real-world skills and procedural acumen. This is precisely where simulation technology enters the picture.

A future-proof LNG training platform

Kongsberg Maritime has developed a pioneering simulation solution for the LNG industry. The K-Sim Engine LNG Bunkering software, particularly its Diesel Electric Dual Fuel Cruise Ferry (DEDF42 CF) model, is a simulator that meets international training standards under the IMO’s IGF Code and STCW Convention.

Delivered as for example a PC desktop training system, it allows students and professionals to gain experience in a fully simulated, risk-free environment.

Key training capabilities

At its core, the DEDF42 model is based on a dual- fuel diesel-electric cruise ferry configuration – a setup that reflects real-world operational complexities. Training scenarios and procedures align directly with STCW and IGF Code

specifications, covering:

- Properties and handling of LNG as a low-flashpoint fuel

- Safe working practices and risk mitigation

- LNG bunkering operation protocols

- Fire prevention and emergency response

- Operational principles of dual-fuel generator systems

- LNG supply systems and fuel changeover procedures

The simulator integrates ship/truck/shore bunkering interfaces, allowing learners to simulate complete fuel supply chains from delivery to storage to engine integration. These include:

- Shore-side interface simulation with real- time control of barge, tank, and truck configurations.

- LNG quality monitoring, including methane number, Wobbe Index, and fuel density.

- Connection/disconnection protocols.

- Flow rate and purging control.

- Emergency shutdown and overpressure scenarios.

K-Sim Engine's comprehensive scope makes it possible for students to learn not just the how, but the why, behind each action – a key differentiator in safety-critical operations.

- Leif Pentti Halvorsen, Kongsberg Maritime

A new paradigm in instruction and assessment

One of the standout features of the K-Sim Engine platform is its instructor, monitoring, and assessment system, which transforms how maritime instructors manage student learning and performance. This instructor toolset enables:

- Custom station configuration, allowing flexible visibility of subsystems.

- Real-time monitoring of alarms, control inputs, and environmental conditions.

- Recording and replay of simulation sessions for thorough debriefs.

- Automated assessment and reporting to track individual student performance, even when simulations are run unsupervised.

- Developed in collaboration with experienced instructors and regulatory bodies such as the Norwegian Maritime Directorate and DNV, this tool is built not only for compliance, but for pedagogical excellence.

Real-world impact

Few institutions exemplify the practical application of this technology better than STC Group in Rotterdam, the Netherlands. As a major training hub for Europe’s maritime workforce, STC Group adopted Kongsberg Maritime’s LNG bunkering simulation technology to meet rising industry demands.

The success of this implementation is not merely academic. STC has reported that students using the K-Sim system demonstrate significantly improved understanding of LNG processes, heightened situational awareness, and better preparedness for real-world emergencies. The ability to replicate complex bunkering operations, including error scenarios and fault management, has made the simulator an indispensable part of their advanced maritime curriculum.

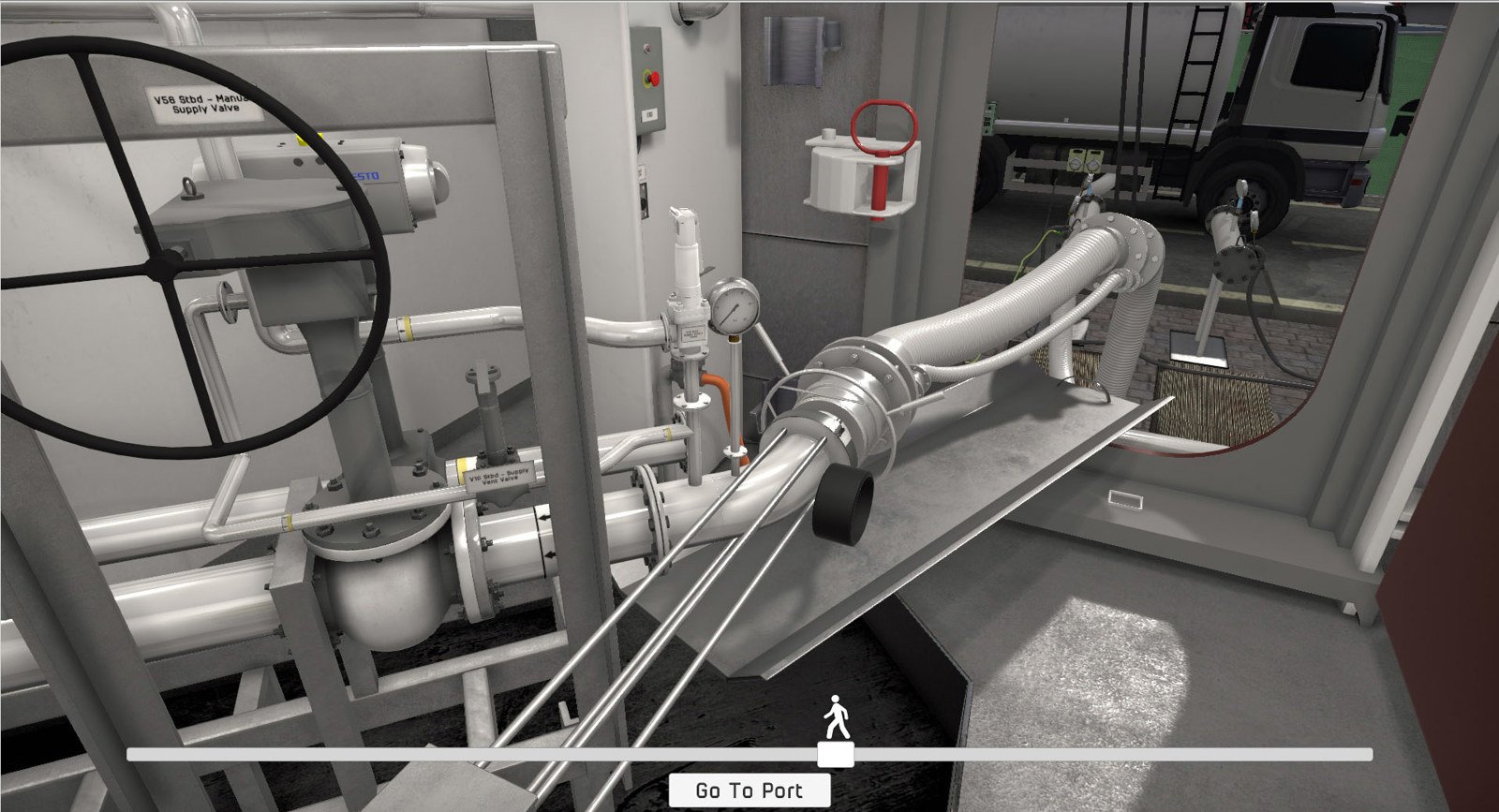

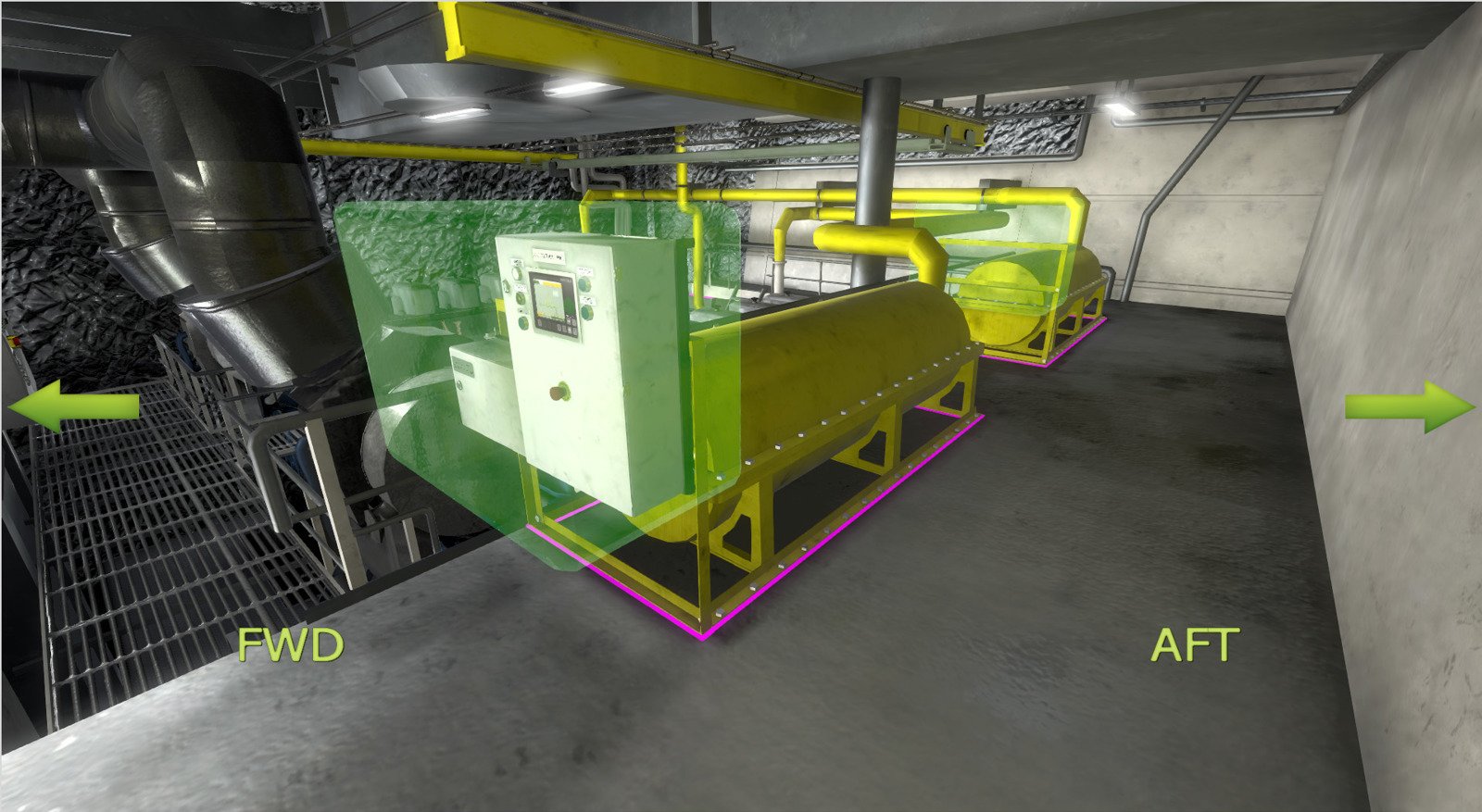

Screen shot from the K-Sim Engine LNG simulation model showing the bunkering operation displayed in the model's 3D walkthrough system.

Bridging the skills gap in a decarbonising industry

As shipping pushes towards decarbonisation, the LNG transition is just one phase in a larger maritime energy evolution. However, LNG is currently the most scalable and mature low-emission solution available, especially for large ocean-going vessels. This reality makes the training of LNG-ready seafarers an urgent global need. Technology such as Kongsberg Maritime’s K-Sim platform plays a critical role in this transition by:

- Reducing training costs through risk-free, repeatable exercises.

- Ensuring safety by instilling correct procedural behaviour before trainees step aboard a live vessel.

- Improving compliance with evolving international regulations.

- Boosting confidence among maritime professionals to oversee next-gen fuel systems.

Simulation as the bedrock of modernisation

The maritime sector is being reshaped by environmental necessity and LNG is a central player in this transformation. However, technology is only as safe as the people who operate it. By integrating robust, regulatory-aligned simulation systems like the K-Sim Engine DEDF42, companies such as Kongsberg Maritime are not just creating tools – they are empowering a new generation of engineers and officers to lead safely into the LNG future.

Simulation is not a luxury; it is a necessity. In the case of LNG bunkering and dual-fuel propulsion, it is arguably the most effective way to deliver compliance, competence, and confidence all in one solution. As case studies like STC Group have shown, the impact is both immediate and enduring.