KONGSBERG Condition Monitoring Solution

Move from reactive to Condition-based maintenance and increase equipment reliability, decrease unplanned downtime, and reduce Opex

Hardware failures are the root cause of almost half of unplanned downtime events – considerably reducing your operational uptime and resulting in significant profit losses.

No matter your vessel type, KONGSBERG’s Condition Monitoring Solution (K-CMS) provides both crew and management with actionable information on the condition of your vital onboard equipment:

- Giving you the power to continually analyse machinery, identify issues and plan your response

- Enabling you to optimise predictive, condition-based maintenance (CBM)

- Making costly breakdowns and operational disruption the exception, not the rule

- Reducing the risks associated with asset ownership

The benefits

-

Maximised asset reliability, performance, and uptime

Maximised asset reliability, performance, and uptime

-

Minimised unplanned maintenance and cost

Minimised unplanned maintenance and cost

-

Improved sustainability through reduced fuel consumption and emissions

Improved sustainability through reduced fuel consumption and emissions

-

Lower operational expenditure and increased profitability

Lower operational expenditure and increased profitability

How it works

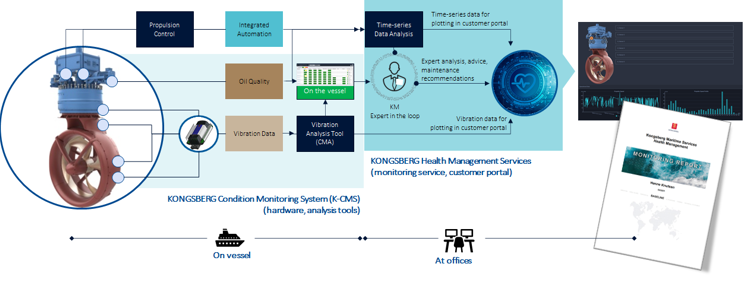

K-CMS is our holistic, class-approved solution for the condition-based maintenance (CBM) of all the critical rotating machinery onboard your vessel. It’s underpinned by our comprehensive knowledge of sensor technology, high-speed processing technology, and secure data handling, delivering:

- High-quality sensors and data acquisition hardware – automated collection of vibration and oil quality data enables the continuous survey of machinery (CSM)

- Data analysis and presentation software, including our Vibration Analysis Tool (CMA) –provides an equipment analysis overview to support maintenance optimisation

- Secure data infrastructure and cloud connectivity – data can be sent ashore for remote monitoring and review, including within our Health Management Service.

KONGSBERG’s Health Management Service places our certified specialists with deep domain expertise in the loop to verify findings and give valuable, targeted recommendations. Together with K-CMS, our experts help you to better manage and predict maintenance and optimise the performance of all your critical equipment.

Why choose K-CMS?

-

Deep domain expertise

Harnessing our extensive knowledge of the whole value chain, we build fully integrated hardware and software solutions that work with the way you work

Deep domain expertise Harnessing our extensive knowledge of the whole value chain, we build fully integrated hardware and software solutions that work with the way you work

-

Holistic service

Monitors all equipment critical to your operations, including 3rd party machinery, within one holistic platform – leveraging highly scalable technologies to provide an overview of your vessels and fleets

Holistic service Monitors all equipment critical to your operations, including 3rd party machinery, within one holistic platform – leveraging highly scalable technologies to provide an overview of your vessels and fleets