Perfecting navy propellers

For over 80 years, Kongsberg Maritime has been perfecting propulsion for all types of naval platforms, from fast patrol craft to aircraft carriers. The key to this success is the Kongsberg Hydrodynamic Research Centre in Sweden, one of the world’s leading marine research facilities. Patrik Kron, Kongsberg Maritime’s Chief of Naval Systems, explains how this facility has been key in developing bespoke propulsion solutions to 70 navies worldwide

The Kongsberg Hydrodynamic Research Centre (HRC) puts us at the forefront of marine technology research and makes a significant contribution to the efficiency and mission-critical performance of many of the world’s navies.

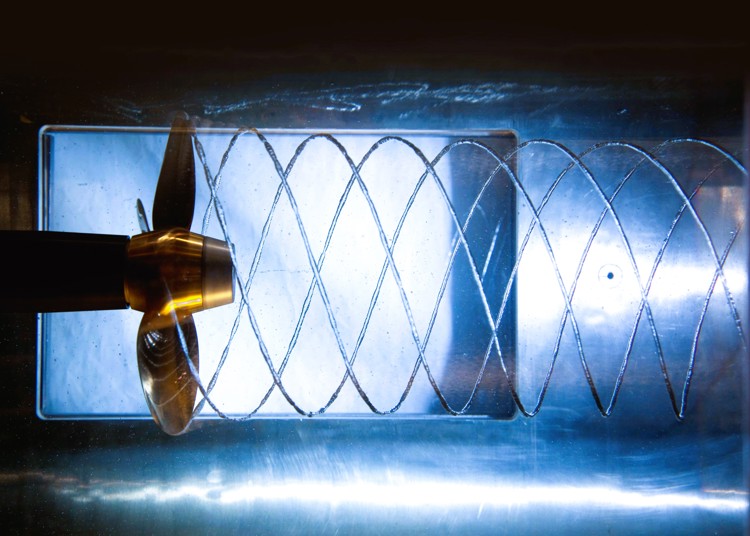

The HRC has two cavitation test tunnels, where water is circulated to assess the performance of a ship’s propulsion system. The tunnels simulate a wide range of vessel operating conditions on the propulsor.

We are unique in that we are the only propulsion manufacturer to have our own in-house research facility. This gives us several advantages that are popular with commercial and naval customers alike. We have developed, tested, and delivered more than 1,500 propeller designs for commercial, governmental, and military vessels.

We can have tight control of a full testing regime, and we can react quickly to design changes, which gives us an additional form of verification.

Our engineers develop propeller designs digitally using the latest computational fluid dynamics (CFD) technology. Such is the computing power available at the HRC, propellers can be modelled in minute detail and in combination with the hull form and operating profile of any ship. We can create scale models of propellers, which are then tested in the tunnels, and this gives extra validation on the performance of new designs.

Depending on the results of these tests, propeller profiles can be altered and refined to give optimum designs suited to specific vessels and operating conditions.

Each navy has its own distinct requirements. While we can draw on a huge amount of data, the propellers we produce for navies are completely bespoke items.

The propeller design is adapted to the size of the ship, its speed, noise, and vibration requirements, and whether it needs to be able to go through ice. For navies, the sound signature of the propulsion system can be a key factor, as can the speed requirements.

For navies, the sound signature of the propulsion system can be a key factor, as can the speed requirements

Fuel efficiency is also becoming a more important issue for navies, more so than it was just a few years ago. We can learn from the work we’ve done in commercial shipping, where fuel cost reduction is a priority, and small changes to propeller designs and operating profiles can bring relatively quick savings.

For navies, any fuel saving translates into a key capability – range extension. Our Promas propulsion system, now available to navies, is a great example of where a product with more than 200 references in commercial shipping can bring benefits for certain naval platforms.