The Hybrid Triple Screw System boosts efficiency and manoeuvrability for Ropax ferries

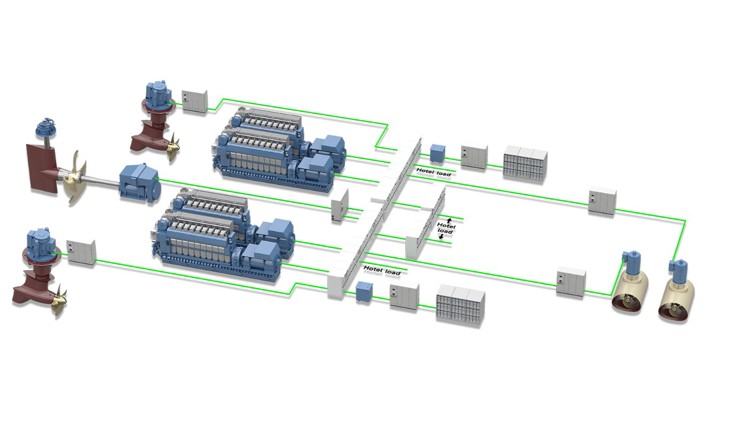

Kongsberg Maritime has combined a conventional propeller shaftline system with twin azimuth/pod thrusters for higher efficiency in transit and better manoeuvrability in port

In an industry first, Kongsberg Maritime can offer new build clients a unique propulsion system that combines a large, centrally aligned shaftline propeller with twin Azipull thrusters or ELegance PODs as “wing” units.

This Hybrid Triple Screw arrangement gives vessels new levels of flexibility and redundancy in their operations. Vessels can enjoy the excellent manoeuvrability that comes with azimuth propulsion, while getting better efficiency and performance while in transit at sea together with the conventional propeller and shaftline system.

Internal studies demonstrate that the Hybrid Triple Screw System allows for a more efficient creation of thrust during all phases of vessel operations.

The system can be installed in combination with hybrid propulsion systems, with solutions possible for more than 30MW of installed propulsion power.

Internal studies demonstrate that the Hybrid Triple Screw System allows for a more efficient creation of thrust during all phases of vessel operations. Results show that the system has less power consumption than either a double CPP configuration or a single screw CPP configuration.

Scandlines, whose ferries connect Germany and Denmark, has adopted the Hybrid Triple Screw System on two of its ferries. In addition to advantages in fuel savings these ferries enjoy while in transit, they can more easily operate in the shallow waters of their ports.

These 170-metre ferries, Berlin and Copenhagen, use twin Azipull thrusters of 3500kW on the wings and a central CPP with 9000kW. They are powered by two 4500kW engines and one 4500kW hybrid engine and have a service speed of 21 knots. Both vessels are fitted with Promas CPP and rudder system, which is optimised for maximum efficiency. The central propeller can be feathered completely.

During in-harbour manoeuvring, Berlin and Copenhagen can use their Azipull thrusters, which have a shallower draught and don’t kick up sediments that can damage propeller equipment. While in transit, the ferries can rely on their centreline CPP to achieve maximum efficiency.

The results of in-house testing using a Ro-Pax ferry design of 98 metres showed that, while underway at a speed of 20 knots, the Triple Screw System has a power requirement 2.5% less than a twin CPP system, and nearly 10% less than a single CPP system.

It is not just ferry operators that can benefit from the Hybrid Triple Screw System. Scandinavian coast guards are also considering the system, thanks in part to the excellent dynamic positioning ability that comes with pod systems, while still enjoying the power benefits from the central propeller and shaft.

For more information: