Tomorrow’s ship solutions today

Kongsberg Maritime’s 2000 TEU open-top container feeder concept adopts the principle of future-proofing from the bottom up, so that shipowners can invest in tomorrow by starting now

-

Text:Marketing & Communication Department

Photo:©Kongsberg Maritime

-

Gunvor Hatling MidtbøVice President, Communications

Container vessels are vital to global commerce. However, the sustainability of transporting goods thousands of miles is also a key focus when considering the fragility of endangered ocean ecosystems. For these two opposing arguments to find resolution, it is clear that an environmentally responsible, cost-effective cargo vessel solution must be a priority for the shipping industry.

The demand for container vessels is currently at record levels, highlighting the need for new ships and the market’s readiness to invest in them. But this readiness is nevertheless tempered with caution: while tightening regulations, green targets, and the desire to reduce operational costs make it clear that change is needed, the details of that change are still unclear. This uncertainty, centred around emissions reduction and the expected transition to zero-carbon fuels, makes it difficult for investors to decide how best to spend their money, fearing that a new vessel may become uncompetitive before it has returned their investment.

Kongsberg Maritime has been working on ways to meet the coming needs of the container shipping industry for some time. In anticipation of new environmental regulations and customer demands, they have combined existing and new technologies with innovative digital solutions to propose a design for a future-proof cargo vessel that shipowners can order today, secure in the knowledge that their purchase will still be competitive and relevant for many years to come

Modular design

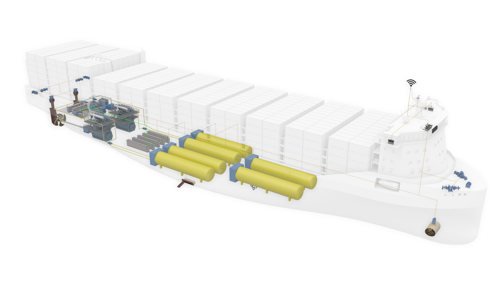

KM’s extensive research, planning and testing is initially focused on the feeder market, with an innovative new design for a 2000 TEU vessel. Targeted as a sensible long-term investment by keeping purchasing and operating costs to a minimum, the open-top, Kielmax (and potentially ice class) vessel has no need for heavy cargo hatches, reducing cost, weight and handling. A forward deckhouse will help protect the cargo against green water coming into the ship, with tarpaulins to provide further protection for the containers, which will slot between tall cell guides. “These partitions are watertight below the main deck and mesh above,” says Oskar Levander, SVP Business Concepts, Kongsberg Maritime. “The cell guides will speed up the loading and unloading process, because the containers don’t need to be lashed so much: on more conventional container ships, they’d normally need to be tied down to each other.

“By making vessels which are efficient at port operations, we can facilitate fast turnarounds with fewer crew members required. Saving time in port allows vessels to maintain their schedule with lower speeds at sea, and consequently reduced fuel use.”Oskar Levander, SVP Business Concepts, Kongsberg Maritime.

Modular design allows for reconfiguration

The vessel has a modular design which can be readily reconfigured to allow for later installation of battery containers and any other future innovations requiring extra space, such as additional tanks for alternative fuels. These can be located below the container stacks without reducing the cargo intake, since the number of containers that can be placed on top of one another is limited by the container strength, not the space in the ship. This is a fundamental aspect of the design, with ample stability afforded by the vessel’s wide beam.

Stability can be further enhanced with Kongsberg Maritime’s optional container loss safety system, which combines active stabilisers with intelligent weather routeing and steering to minimise the risk of cargo loss – a scenario already rendered unlikely by the use of cell guides.

New fuels

Perhaps the most pressing dilemma to be addressed is fuel choice. “A shipowner can be quite certain that if they buy a ship today, that ship will experience fuel transition during its working lifetime,” says Levander. “So how do you prepare for that? Our solution is to design a ship that can easily evolve with time. The fact that its components will definitely be changed and upgraded has been taken into consideration from the very beginning.”

Kongsberg Maritime’s approach is to start with LNG, which gives a solid basis for conversion to most of the alternative future fuels currently being suggested. “There is already an infrastructure for LNG – we can use it now,” explains Levander. “In time, shipowners can easily switch to carbon neutral liquid biogas or synthetic LNG, using the same engine whenever that fuel becomes available at an attractive cost, because it’s essentially the same fuel. Basically, LNG is methane, biogas is methane and synthetic LNG is methane: it’s the same molecule, it’s just produced in different ways.

“In addition, through use of dual-fuel engines, vessels can also operate on diesel or renewable options such as HVO [Hydrotreated Vegetable Oil]. Operation with ammonia will be possible via a conversion, which we will make as simple and cost-effective as possible. With multiple current and potential future fuels applicable to their vessels, shipowners can be confident that they are safeguarded and ready for the next steps.”

Choosing any of these fuels will result in a dramatic drop in greenhouse gas emissions compared with MGO. Our figures show that LNG results in a 18% drop, while BioLNG and ammonia slash CO2eg emissions by up to 85%.

Accordingly, the 2000 TEU’s design principles accentuate adaptability, accommodating potential alternative fuel solutions as a matter of course to make it a sensible and economically attractive mid- and long-term proposition for shipowners. Most of the fuel system components are modular, plug-and-play items which are easy to retrofit, upgrade and convert. Other, more expensive parts such as engines and tanks will be able to smoothly weather the transition with only minimal adjustments to parts such as valves and connections.

Fuel storage is one of the most likely areas to demand significant change, especially for high-volume fuels such as ammonia. The two pre-installed C-type LNG tanks have been designed to be ammonia-ready, and the open-top, modular design makes installing further storage as simple as possible with the option to add extra tanks below the cargo.

At the core of our solution is the installation and integration of a hybrid shaft generator as standard, enabling both PTO (Power Take Off) and PTI (Power Take In) functions. Research carried out by our Business Concepts team on a variety of vessels has demonstrated that use of a PTO can deliver significant efficiency benefits by leveraging unused power generation capacity from the propulsion engines and reducing the level of auxiliary generator support required for vessel operations. This delivers fuel savings together with lower emissions (CO2eg) of up to 15%, and is especially beneficial in reducing methane slip by minimising use of the four-stroke auxiliary engines.

Adding batteries – a process made simple by the modular design of the 2000 TEU container feeder – takes this a step further. The PTO can be used to charge batteries when the engines are running at otherwise low loadings. This stored power can then be used for a range of purposes including blackout reserve, spinning reserve, peak shaving and – an option which will doubtless be attractive in sensitive areas – to power the unit as a PTI for zero-emission propulsion and cargo transfer operations. In the future, zero-emission operation may become essential in seaways close to populated areas: this solution could be upgraded to make sheltered voyages such as the Kiel Canal transit possible on battery power alone.

Two propulsion configurations have been suggested. A single-screw version benefits from lower hydrodynamic resistance and lower investment costs, while a twin-screw option trades higher hull resistance and investment cost to yield better open-water efficiency and manoeuvrability in port. This last point could reduce time in port and the need for tugs, with consequent savings in time and operating costs.

For wind, our calculations with Flettner rotors suggests that an annual fuel saving of around 8% is possible. This is based on using two tilting rotor sails, a choice which will facilitate port operations and reduce resistance in headwinds. Research is currently being carried out to investigate the effect of using a larger number of smaller, fixed rotor sails.

Kongsberg Maritime also proposes deployment of the HullSkater solution, a proactive hull-cleaning robot jointly developed with Jotun, which will deliver large fuel savings by removing fouling at an initial stage, before it becomes strongly attached to the hull.

DIGITAL SUPPORT

Where any future-proof vessel design is concerned, digitalisation will sit right at its heart. On board the 2000 TEU container feeder vessel, our EcoAdvisor tool forms the core of the system, advising on the best configuration to optimise fuel use, maintenance, environment or safety, depending on the current operation.

This ‘smart ship’ ethos represents not only a means of improving operational safety, efficiency and regulatory compliance, but also of removing the barriers between fleets and shoreside teams. The 2000 TEU container feeder is accordingly foreseen as a digitally advanced ship, primed to take advantage of evolving remote support and autonomous technologies while also benefiting from our full picture solutions for automation, systems management and optimisation.

KONGSBERG’s Vessel Insight SaaS (software as a service) solution, its patented ship-to-cloud data infrastructure, is a key feature of the concept in terms of capturing, aggregating and securely transferring standardised, high-quality, vessel-specific data from the container feeder. The company is keen to emphasise that this service can help to enhance the future commercial trajectory of its customers: it hosts sophisticated data analysis tools and acts as an access portal to other applications and services in the Kognifai maritime marketplace, KONGSBERG’s open digital ecosystem, that could leverage their fleet and vessel data for optimal business value.

The potential for transformative long-term growth in the cargo shipping segment is clear, but the environmental and regulatory clocks are ticking, and shippers need to start taking the appropriate steps for fleet renewal as soon as possible. A revised IMO strategy for the reduction of greenhouse gas emissions from ships will be adopted in 2023, meaning that vessels will need to meet even more exacting CII (Carbon Intensity Indicator) and EEXI (Energy Efficiency Existing Ship Index) targets.

Kongsberg Maritime’s 2000 TEU concept is estimated to have a CII value 34% below the target line, which should allow shipowners to maintain a CII A-rating for at least 10 years. Taking a holistic view from well to wake, adoption of a novel design with LNG, PTO and wind technologies results in a total decrease in emissions of 36% compared with a conventional MGO-fuelled vessel, of which 12% is attributable to LNG use, 15% PTO operation and 5% wind and remaining improvement to the new ship design.

These figures are obtained by using LNG fuel with a PTO: currently sustainable fuels are scarce and have little or no distribution infrastructure, making them an expensive choice. Nevertheless, initial calculations for BioLNG show that even in today’s market, a modest (17%) increase in total annual costs – based on estimated fuel costs and efficiency improvements of the new design – can achieve emissions reductions of up to 85%. As infrastructure expands and carbon tax increase, this will be a strong contender for sustainable operations, deliverable with no modification to the 2000 TEU vessel design.

Taking the next step

In one sense, it can appear that the maritime cargo sector is at a crossroads, compelled by law, commerce and circumstance to embark upon the next decisive step towards a green, digital future, yet wary of commitment when specific details about the path ahead remain unclear. The good news for shipowners is that future-proof, technology-ready solutions are waiting in the wings. Companies such as Kongsberg Maritime have been putting in the hours, developing future-ready solutions such as the 2000 TEU container feeder vessel to help their customers adopt prudent, rational and beneficial long-term strategies when it comes to investing in the next generation of cargo fleets.