Today’s navies need flexibility. They want multi-purpose ships that can quickly adapt to the ever-changing battlespace. Add to that the rapid growth in varieties of manned and unmanned craft being deployed from modern naval ships. Kongsberg Maritime’s all-new Mission Bay Handling System has all the elements that can transform naval capability.

With more than 30 years’ experience in developing advanced handling systems for the safe and efficient deployment of subsea equipment, Kongsberg Maritime has drawn on its rich pedigree to develop a flexible handling solution specific to today’s naval requirements.

“Modularity is the buzzword,” says Robert Breivik, Kongsberg’s Senior Sales Manager – Naval. “I speak to a lot of navies, and the one thing they all want is modularity. Navies want platforms that can easily be transformed to meet the mission requirements, so the days of ships that are dedicated to a small range of tasks are over.

“The global security arena is changing, and navies must be ready to adapt quickly. Areas like underwater surveillance and the monitoring of seabed utility assets like pipelines and cables, is an urgent requirement. Modern ships need to be multi-role, and that means carrying a growing suite of newer, high-tech in-sea assets.”

The latest technology means the best possible results for our customers around the world

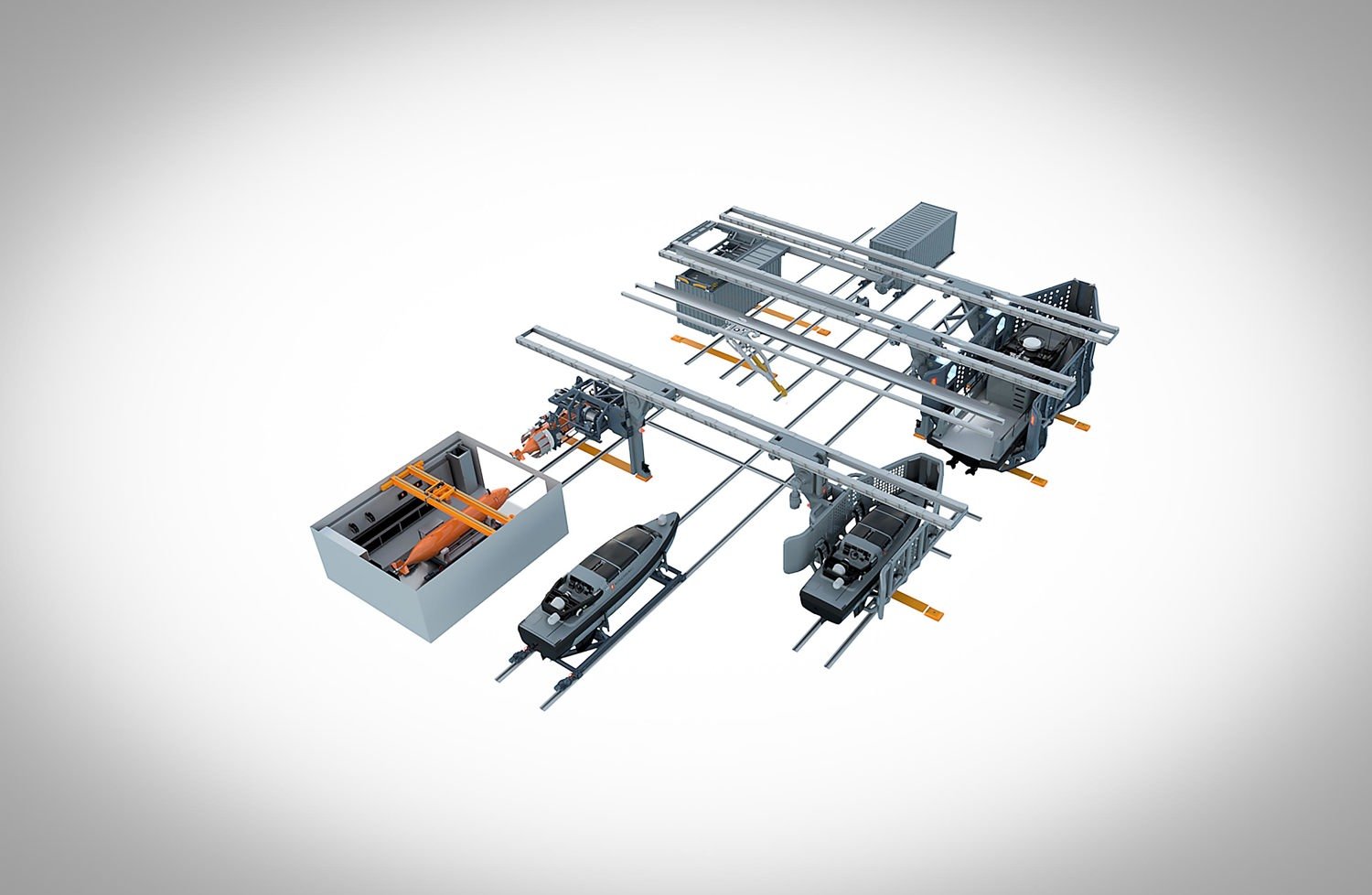

Getting those assets from and to the mothership in a way that’s quick, safe and effective, is at the core of the thinking behind our new Mission Bay Handling System. Suited to a wide range of naval ships, and fully adaptable to suit the size of the mission bay, the new system comprises three elements: a frame system; overhead crane system and stand-alone cargo handling solutions.

First, the frame system offers a fully interchangeable rail system that is fixed to deck above the mission bay, meaning in-sea assets are suspended from the rails and can be moved easily from their storage spaces within the mission bay.

The overhead system has a standardised interface with the ship, which comprises the rails and an ‘interface unit’ which is suspended from the rails and connects to a range of tools. The tools are all interchangeable, and it’s easy to change the handling tools without altering the frame.

-

Clean deck

No permanent tripping hazards or obstacles installed on the deck.

-

Modular

Built from a variety of flexible handling systems.

-

Adaptive

Designed to fit hangars with different dimensions and shapes.

-

Time saving

Mobilisation and demobilisation made easy.

-

Cost reduction

No need for costly rebuilds between each mission setup.

There is a choice of a single or dual rail system. With a single rail, loads of six tonnes can be handled, and if doubled up to two rails, a 12-tonne capacity is achieved.

The Mission Bay Handling System also offers an overhead multi-purpose hangar crane option. It can handle 10’ and 20’ ISO containers up to 15 tonnes for general cargo. The crane can rotate through 360 degrees, and with a telescopic boom can extend to the water level. The task of deploying and retrieving ‘daughter’ craft, with personnel aboard, is easily achieved, with a capacity of 10 tonnes.

“Through our extensive experience from a lot of similar systems we have developed for oceanographic and research ships, this crane is not only very capable, but it gives navies options. It can handle cargo in standard shipping containers, and switch to deploying subsea and surface craft, quickly and safely,” adds Breivik.

The third element of the handling system is a series of stand-alone cargo solutions, which can be added to the mission bay to supplement those mentioned above. There are three solutions available: Deck Skid System; a cargo handling crane for containers, and an overhead auxiliary crane, for lighter loads up to 1.2 tonnes.

The Deck Skid System is fully electric, modular and adaptable to suit the easy movement of ISO containers, pallets or a boat cradle.

The ceiling mounted cargo handling crane can lift 20’ ISO containers, and features two electric lifting winches and dual telescopes for increased flexibility and reach.

The handling system ensures containers can be moved easily