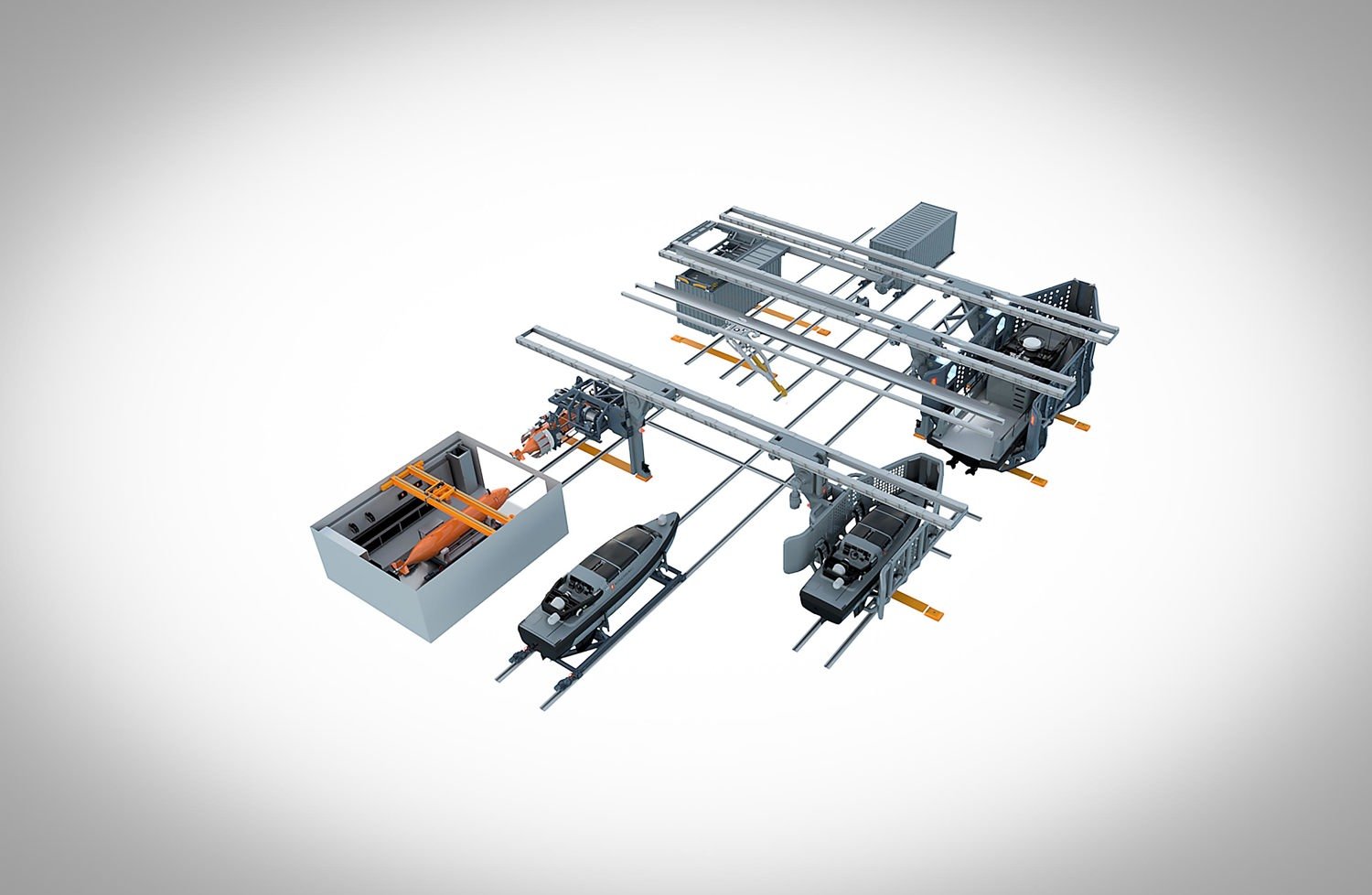

There is a choice of a single or dual rail system. With a single rail, loads of six tonnes can be handled, and if doubled up to two rails, a 12-tonne capacity is achieved.

The Mission Bay Handling System also offers an overhead multi-purpose hangar crane option. It can handle 10’ and 20’ ISO containers up to 15 tonnes for general cargo. The crane can rotate through 360 degrees, and with a telescopic boom can extend to the water level. The task of deploying and retrieving ‘daughter’ craft, with personnel aboard, is easily achieved, with a capacity of 10 tonnes.

“Through our extensive experience from a lot of similar systems we have developed for oceanographic and research ships, this crane is not only very capable, but it gives navies options. It can handle cargo in standard shipping containers, and switch to deploying subsea and surface craft, quickly and safely,” adds Breivik.

The third element of the handling system is a series of stand-alone cargo solutions, which can be added to the mission bay to supplement those mentioned above. There are three solutions available: Deck Skid System; a cargo handling crane for containers, and an overhead auxiliary crane, for lighter loads up to 1.2 tonnes.

The Deck Skid System is fully electric, modular and adaptable to suit the easy movement of ISO containers, pallets or a boat cradle.

The ceiling mounted cargo handling crane can lift 20’ ISO containers, and features two electric lifting winches and dual telescopes for increased flexibility and reach.