Into the wind

Offshore wind farms are set to boom over the next few years, becoming an ever more popular way of meeting the world’s sustainable energy needs. KONGSBERG is providing the state-of-the-art technology solutions needed for this green power revolution

-

Text:Marketing & Communication Department

Photo:@ Equinor

-

Craig TaylorSenior Manager PR & Communications

Offshore wind farms are set to play a major part in meeting the world's sustainable energy needs. Their location out at sea means they can be larger and taller than their onshore counterparts, making generation more efficient.

They are more environmentally friendly, less visually intrusive and are not hampered by physical intrusions that could adversely affect wind flow. By facilitating mass production of low or zero carbon energy, they make a major contribution to UN sustainable development goals (SDGs).

As a hugely experienced operator with decades of specialised experience in offshore energy operations, KONGSBERG is extremely well placed to support the projected rapid global growth in wind farms.

We see this as one of our most important future markets in both the short and the long term. Our focus on innovation and integration in the energy sector positions us as a major player in sustainable generation as the world moves away from fossil fuels.

The economic and environmental potential of offshore wind is huge. Research has projected that its global value is set to reach $120 billion by 2030, with a total turbine output of more than 65000 MW*.

Many of the competences required for surveying, building and maintaining offshore wind infrastructure are similar to those deployed on projects involving traditional oil and gas platforms. This is an area in which we have long had a presence.

Moving into offshore wind allows us to build on the pioneering maritime solutions we have already delivered, including the first dynamic positioning systems and autonomous underwater vehicles. We have also invested in a significant number of digital and operational technology advances.

The expertise we have developed over many years means that we can bring dynamism, drive, innovation and unrivalled expertise right across the four distinct phases of an offshore wind farm’s life cycle:

This work is done at the pre-survey and survey phase. KONGSBERG's world-class hydroacoustic offerings deliver accurate and reliable mapping of the subsea environment, identifying the seabed geography as well as obstructions, hazards, sediments, water depth and current flow.

This data is critical when it comes to wind farm construction. The company also has the capability to analyse important metrics such as seabed soil, mobility of sediments and archaeological assessment. In addition, it possesses the ability to carry out burial depth analysis for the subsea infrastructure of turbines.

All these KONGSBERG offerings help provide the critical information needed to operate an offshore wind farm using hundreds of individual turbines efficiently and with the lowest possible maintenance cost over decades – something that is particularly important given their distance and relative inaccessibility from shore.

Installation

Offshore wind farms are highly efficient at harvesting energy from wind and the technology to achieve this is improving all the time. However, the actual installation of the turbines can be expensive and hazardous. This is another area where KONGSBERG provides vital expertise and support.

Specialised vessels use cutting edge digital and operational technologies to reduce both cost and risk. These can help cut the amount of offshore human intervention required and increase the window of time needed to undertake an installation.

Harmonising engines, propulsion, dynamic positioning, navigation, automation, electrical and digital systems ensure wind turbine installations lower their overall environmental impact.

KONGSBERG technologies allow crew and engineers to access the most recent available data, creating the working environment necessary for safe and accurate operations and making sure that the decisions those involved make are fully supported.

As the offshore wind industry continues to grow and develop over the years ahead at a projected global rate of 8 percent*, installation support services will need to continually be remodelled in order to meet the challenges. Turbines will become bigger and more powerful and wind farm locations will move into more and more distant waters.

Construction vessels and cable layers are proving to be transformational and will be key as the industry and its infrastructure expands and matures, with new innovations making projects safer and available at a lower cost.

KONGSBERG will continue to deploy its advanced technologies to meet the developing needs of the sector.

This is hardly surprising, as these activities represent the biggest single overhead in building and operating an offshore wind farm – in total, they account for nearly 25 per cent of the entire lifetime cost.

That is why driving efficiency is so important. KONGSBERG does this with a whole range of different technology-driven disciplines including vessel power and operations, robotics, autonomous systems, machine learning and artificial intelligence.

Either taken together or individually, these technologies play an important part by transforming the logistics of wind farm service. In addition, they help by ensuring safe transport for technicians who carry out the crucial job of keeping the giant turbines in operation.

KONGSBERG products also act as an operational hub for wind farm infrastructure. For example, online monitoring linked to deep sensor connectivity conveys vital information about a turbine’s position relative to the seabed.

It also provides real-time motion data and remotely examines the subsea footings for damage. Once again, these technologies are essential because they help to lower the amount and cost of maintenance.

Life Extension and Decommissioning

As wind generation technology evolves, turbines are likely to improve and wind farms become more efficient. This means that as an alternative to decommissioning their working lives could be extended. When this happens, KONGSBERG will be ready and able to provide industry leading solutions.

The fact that offshore wind farms are being deployed further and further from the shore means that they have to face increasingly hostile and challenging weather conditions. So, it is inevitable that despite their rugged construction, high standards of construction and durability, the infrastructure will degrade and eventually wear to the point where it is no longer economically viable.

At this point, the turbine is reaching the end of its lifecycle and decommissioning has to be actioned. This can be a complex process and needs to be planned well in advance.

Once again, KONGSBERG provides the technology needed, including the same advanced hydroacoustics solutions deployed at earlier stages of the project to allow safe and efficient wind farm design and installation. These solutions will optimise end-of-life operations and help in the preparation of the necessary technical reports.

By delivering a platform for accurate seabed and environmental surveys, the company provides the data that decommissioning engineers need to optimise and streamline their operations.

In addition, state-of-the-art positioning systems and integrated operational technologies for heavy lift and support vessels generate the relevant and highly accurate data required. This reduces the risk of accidents and allows for more environmentally friendly working.

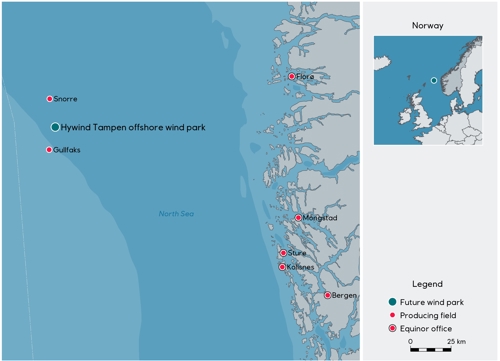

The technology and experience developed at KONGSBERG is also helping to deliver another world first, bringing together traditional fossil fuel production with wind generation from the Hywind Tampen floating offshore wind farm in the Norwegian North Sea.

The 88MW development, consisting of 11 turbines, will provide power to Equinor’s Snorre A and B and Gullfaks A, B and C platforms.

It will be positioned between the platforms some 140 kilometres from shore at a water depth of between 260 and 300 metres. Operation is scheduled for start up at the end of 2022.