With spending on deep-sea exploration reaching all time highs, getting the best seismic information is critical. And with the recent delivery of the first of four Ramform Titan class seismic vessels, Petroleum Geo-Services (PGS) is now able to deliver high-resolution data from more complex geology, faster than ever before.

-

Text:Kongsberg Maritime Communication

-

Gunvor Hatling MidtbøVice President, Communications

Rising global demand for energy has resulted in more spending on exploration in established fields in the North Sea, Gulf of Mexico and Brazil, and in new frontiers such as offshore Greenland, East Africa, Uruguay, the Falkland Islands and South East Asia. And with the energy industry seeking oil and gas in deeper waters and in more complex geological structures, the offshore industry increasingly relies on obtaining quality seismic data from reliable suppliers.

SEISMIC BOOM

Magne Reiersgard, Executive Vice President Operations for PGS notes that new technologies, such as horizontal drilling, have created demand for data not only related to the discovery of new reservoirs, but to appraisals, development and production on existing fields. “Improved seismic data has allowed energy companies to take a second look at subsea fields once considered marginal or nearing the end of their life cycles,” he says. “In my view, the two key drivers in our industry right now are rising global demand for energy, which has spurred more exploration in remote areas, and new technologies which have provided energy companies with access to new sources of oil and gas in existing fields where subsea infrastructure is already in place.”

SIZE MATTERS

For PGS, the boom in demand for seismic data corresponds neatly with the recent delivery of the first of four state-of-the-art Titan Class Ramform seismic vessels from the Mitsubishi Heavy Industry yard at Nagasaki, Japan. These giant, purpose built vessels feature a back deck that spans 70 meters, supporting no less than 24 streamer winches – an industry first. To tow this massive array requires a power plant that produces 1.8 MW from three variable pitch propellers, each providing 6000kW.

In addition to greater streamer capacity, the vessel’s broad stern offers a safe, flexible workspace that enables the crew to undertake maintenance without interrupting vessel operations. Power generation and auxiliary systems are completely separate, and with two separate engine rooms, the vessel is fully operational with just two of her three propellers in service. She’s built to ensure reliable operations – even in marginal weather.

Reiersgard says that the vessel was specifically designed to meet the evolving demands of the offshore industry. “Usually, exploration licenses are limited to three to five years,” he explains. “In harsh environments such as the North Sea, the weather window for conducting seismic surveys is relatively brief. However, Ramform Titan’s ability to cover a large area and operate successfully in marginal weather can often make the difference between getting the job done in one season instead of two or three. That represents a significant cost saving.”

EVOLUTION, NOT REVOLUTION

Since the first Ramform seismic vessel was delivered in 1995, its delta-shaped design has become a trademark for PGS. Indeed, over the years, the Ramform fleet has broken almost all seismic production records, being the first to tow

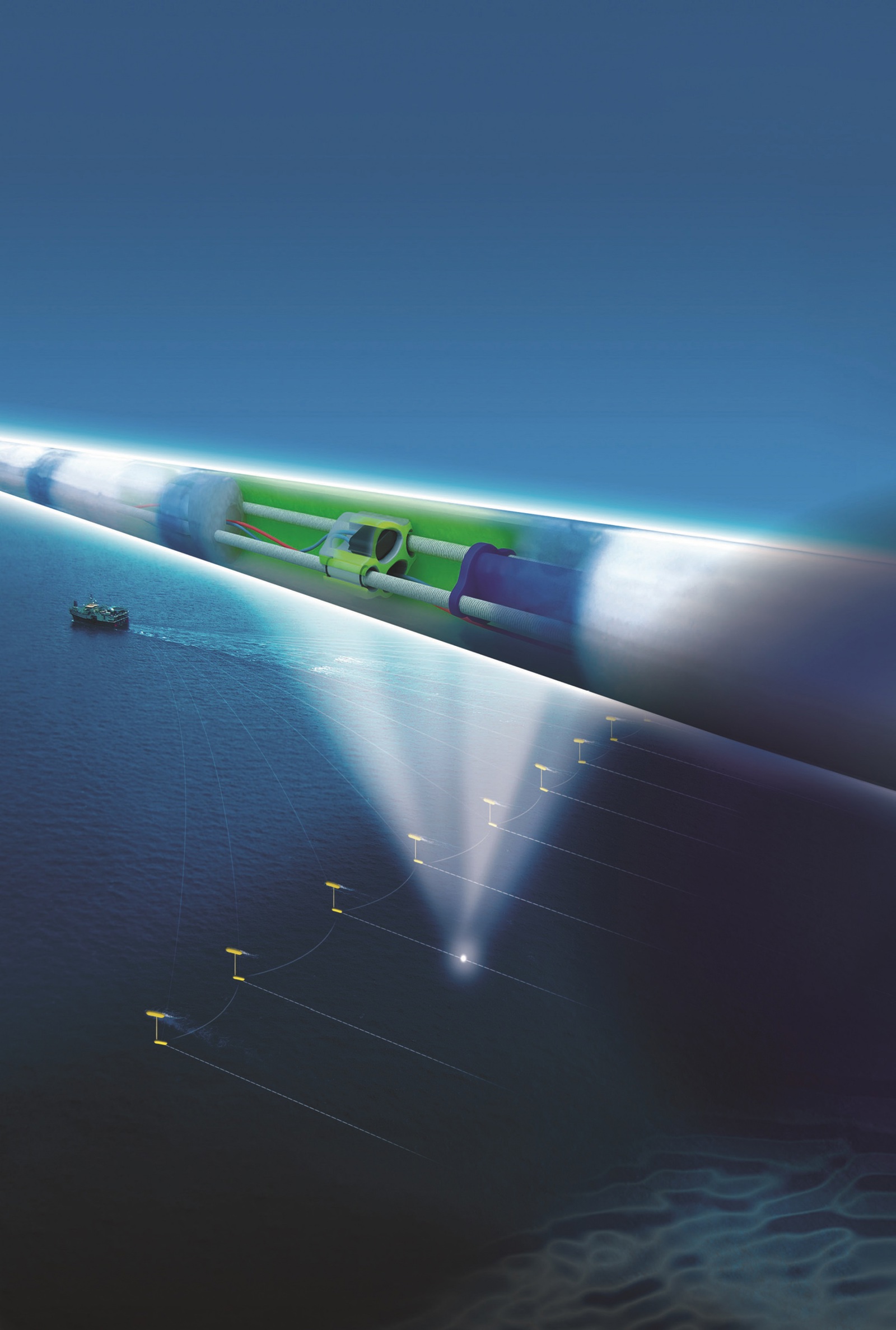

eight, ten, twelve, fourteen, sixteen and seventeen streamers. The Ramform Titan is no exception: the vessel is equipped with no less than 24 streamer reels. 16 are placed abreast across the stern, with eight positioned in a second row on the same deck. This configuration enables faster deployment and provides PGS with increased survey flexibility, improved efficiency and operational safety.

The Ramform Titan is also optimised for eBird Technology, which allows operators to control streamer roll orientation, depth and separation during the survey, including deployment and retrieval. Reiersgard explains that tidal forces or currents often cause streamers to move in different directions – an effect known as “streamer feathering.” These can result in gaps in the data (infill), which may require that the vessel re-survey the same area – leading to delays. “By having more control over the streamers we can offer a more consistent, reliable survey and avoid the risk of downtime,” he says. “We understand that it’s not simply a matter of the area we can survey but the comprehensive quality of the coverage.”

GHOSTBUSTER

The Ramform Titan can offer reliable coverage, but the vessel itself cannot deliver quality data. To achieve this, PGS has developed broadband streamer technologies that provide more accurate 3D and 4D subsurface images of deep and complex subsea geological formations. For years, seismic data had been subject to distortions or “ghosts” caused by sound waves reflecting off the under-surface of the water. Following a multiyear development process, PGS launched GeoStreamer in 2007, a dual-sensor streamer that eliminated sea surface reflections. And in 2011, PGS launched GeoStreamer GS, a unique source technology that significantly improved image quality.

“GeoStreamer has been a real game-changer,” says Reiersgard. “The technology enables far better data on promising subsea fields and provides our customers with the opportunity to upgrade their existing seismic databanks to dramatically improve their imaging and understanding of existing reservoirs.”

PARTNERING FOR SUCCESS

When paired together, GeoStreamer and the Titan Class Ramform vessels make a powerful combination. But while the streamer technology and the vessel design are unique to PGS, the company depends on a network of trusted suppliers to achieve the best results. “We tend to favour long-term relationships with suppliers who share our focus on innovation and reliability,” says Reiersgard. “Kongsberg Maritime‘ s focus on product development, efficient project execution, systems reliability and their global presence made them a natural choice for supplying the systems we needed for the Titan Class Ramform newbuilding programme.”

Gard Ueland, President of Kongsberg Seatex, says that Kongsberg Maritime’s relationship with PGS has intensified over the last six years. “As the complexity of their vessels has increased, the scope of systems we have supplied to them has grown,” he says. “We recognise that they have zero tolerance for downtime, so we have worked to provide them with a broad range of proven, fully-integrated systems and equipment to ensure reliable and efficient operations.”

FULL SPECTRUM DELIVERY

The systems KONGSBERG supplied to the Ramform Titan include integrated navigation and bridge control systems (K-Bridge), Thruster Control Systems, Dynamic Positioning (K-Pos class II), fully integrated hydraulic and winch control systems developed by Kongsberg Maritime subsidiary, Kongsberg Evotec, and eBird streamer control, delivered by Kongsberg Maritime subsidiary, Kongsberg Seatex. While most of these systems required minimal adaptations, the sheer size of the streamer spread meant some modifications to the back deck handling systems. “Supplying PGS with such a broad suite of systems for its Ramform Titan is an acknowledgment of KONGSBERG as a supplier to high-end seismic industry,” says Ueland. “We are very pleased that PGS has selected our innovative solutions and recognises how these systems will benefit their operations.”

For Ueland, working with PGS has been a highly constructive experience. “There is excellent match between PGS as a pioneering and innovative seismic company and what KONGSBERG can offer as an advanced technology and systems provider,” he says. “We feel that our innovative solutions are highly appreciated and bring value to our customers.”

While the DP II system aboard the Ramform Titan is fairly standard, it remains critical to avoiding down time. According to Nils Albert Jenssen, Vice President of Business Development at Kongsberg Maritime, the DP system aboard a seismic vessel enables the vessel to travel on autopilot. “Station keeping remains the most challenging aspect of any dynamic positioning system, but for seismic vessels, the capability to stay on course is critical,” he says. “The integrated sensors on KONGSBERG DP systems account for wave action and current, correcting for variables to ensure the vessel and streamers are optimally aligned at all times.”

A SHIFT IN DEMAND

PGS derives income from two primary sources: performing surveys for individual clients (marine contracts) and developing and acquiring high quality surveys and licensing these to a number of different customers (multi-client). In the past, PGS was more active in marine contracts, but today the mix is more balanced, with a shift toward multi-client. Investing in new streamer technologies and sizing up the capacity and efficiency of a proven vessel’s design, offers advantages in both markets.

Reiersgard explains that the investment focus is driven by market forces: growing demand for oil and gas has kept energy prices high, encouraging more investment in exploration. However, he notes that unlike most shipping companies, PGS’s core offering has little to do cargo space or the number or size of vessels in its fleet. “The quality of our vessels and personnel are essential to our business, but our clients come to us for one reason: good information. To make business-critical decisions, they need reliable, quality data as soon as they can get it. So long as we can meet this demand, we will continue to succeed. Content is king.”