The answer? It’s blowing in the wind

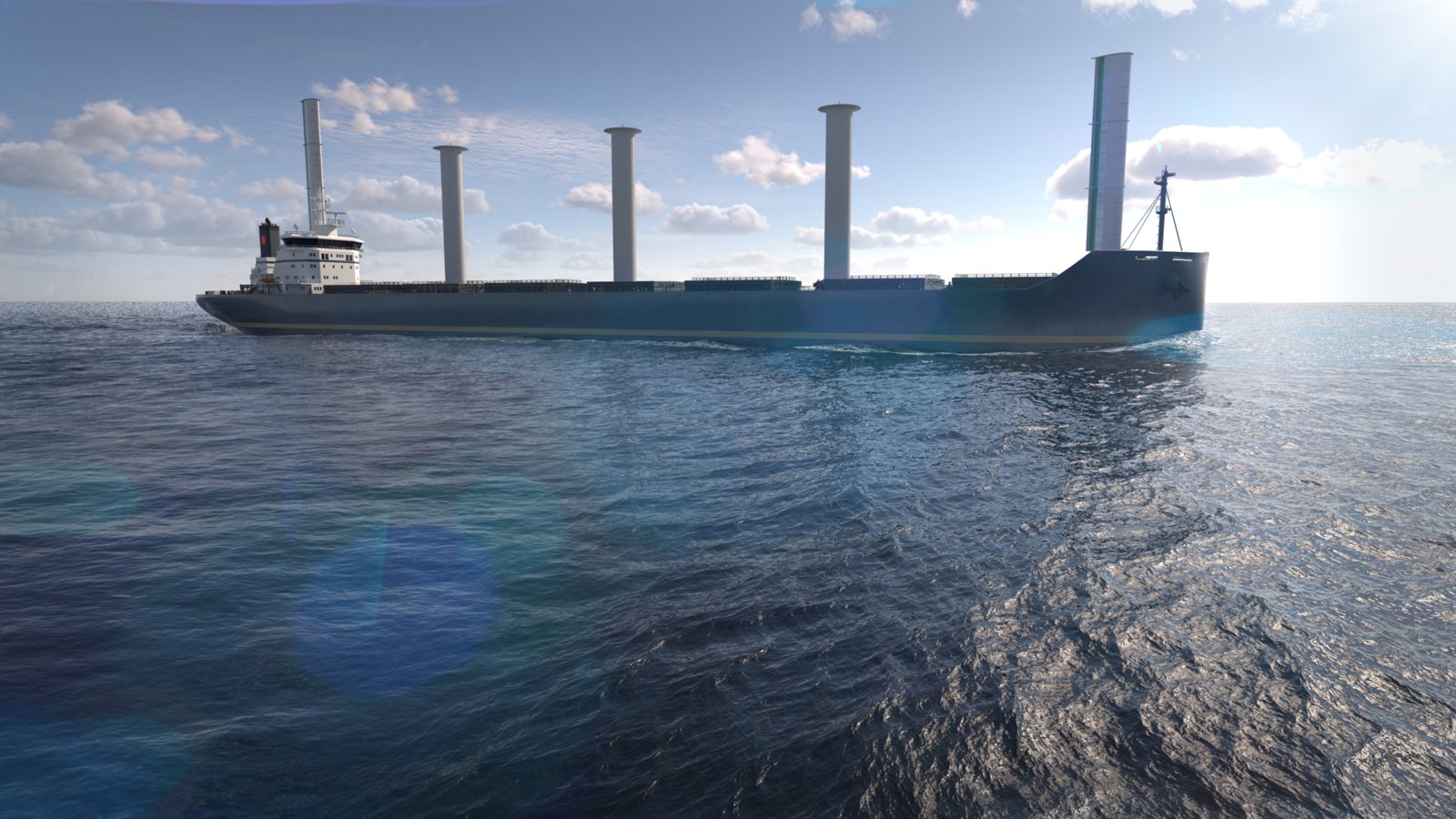

The latest sail technology supplies customers with solutions that are built to endure. They aren’t just a quick fix. Kongsberg Maritime’s K-Sail system provides the power to do things differently in the global shipping industry.

-

Text:Global Marketing and Communication

Photo:©Kongsberg Maritime

-

Craig TaylorSenior Manager PR & Communications

Avariety of wind technologies have gained popularity over the past decade, offering ship owners a relatively ‘quick fix’ in terms of tapping into the power nature to help reduce fuel consumption and emissions on a range of merchant ships.

Kongsberg Maritime, with its extensive experience of integrating technologies across thousands of ships, has developed a new system to integrate wind-assist solutions. More than simply enabling the ‘bolt-on’ of wind technology, K-Sail optimises the use of wind technology as part of a fully integrated ship system and, crucially, adds value to any investment in wind technology.

With a background in aeronautical engineering, Henrik Alpo Sjöblom, Kongsberg Maritime’s Vice President Business Concepts, knows a thing or two about air flow and the forces and interactions between wind and solid surfaces.

Henrik Alpo Sjöblom, Kongsberg Maritime’s Vice President Business ConceptsWind-assist technologies are great way of providing thrust to boost the propulsive power of a ship. Wind is essentially a free source of energy, but managing the way it is used, alongside all the other variable systems on ship is the key to maximising the use of this natural resource.

Henrik explains: “K-Sail is a solution where we make different ship equipment play with each other, better. Putting a sail on a ship is of course not new. But the essence of using it successfully lies in the integration of these sails into the ship’s systems.”

Versatility and integration

One of the key features of K-Sail is its versatility. Henrik emphasises: “Regardless of the sail type that a ship owner selects, our system remains the same, it can work with them all. In fact, it can even work without sails on vessels with high windage like a car carrier, as an example.”

The integration process involves analysing the vessel and its operational route, selecting the appropriate sail technology and then optimising the ship’s systems around this technology. The optimisation process for K-Sail is comprehensive and divided into five key areas.

First, the analysis phase involves understanding the vessel’s operational parameters and selecting the appropriate sail technology. This step is crucial for tailoring the solution to the specific needs of the ship and its route. Next, steering optimisation is performed to adjust the steering system, accommodating the additional thrust generated by the sails. This ensures that the vessel maintains optimal manoeuvrability and control.

Following this, propulsion optimisation is carried out to ensure that the propeller operates efficiently with the added wind propulsion. This step maximises the propulsion system’s performance, contributing to overall fuel savings. Power management is another critical area, where the power generated by the sails is balanced with the ship’s energy requirements. This involves integrating the sails into the ship’s energy management systems to ensure seamless operation.

Finally, voyage optimisation uses AI and real-time data to optimise the vessel’s route and speed for maximum efficiency. By considering factors such as wind, currents and waves, this step ensures that the vessel operates at peak efficiency throughout its journey.

K-Sail provides real time analysis of all these variable factors.

Wind technologies at a glance

Kongsberg Maritime is committed to working with sail providers to integrate their technologies into larger ship systems. By collaborating with various wind technology manufacturers, K-Sail ensures that each sail type is optimised for performance, contributing to the overall efficiency and sustainability of the vessel.

-

These cylindrical sails harness wind energy through the Magnus effect, creating a force perpendicular to the wind direction. Flettner Rotors are known for their high performance on a small footprint and can be easily retrofitted to older vessels. K-Sail can integrate Flettner Rotors into the ship's propulsion and steering systems, ensuring optimal performance and fuel savings.

Flettner Rotors: -

Suction sails use an aerodynamic thicker wing profile to generate lift, maximising efficiency. These sails are particularly effective for general cargo ships. K-Sail supports the integration of suction sails by optimising the ship’s power management and energy systems to complement the additional thrust provided by the sails.

Suction sails: -

Traditional soft sails are still widely used and can be adapted for modern commercial vessels. K-Sail can integrate soft sails into the ship’s existing systems, ensuring they work in tandem with the propulsion and steering mechanisms.

Soft sails: -

Rigid sails, such as WindWings® and OceanWings®, offer a robust and efficient solution for wind propulsion. These sails are designed to withstand harsh maritime conditions and provide significant fuel savings. K-Sail can integrate rigid sails into the ship’s energy management systems, optimising their performance and ensuring seamless operation.

Rigid sails:

Wind power driving Tärntank’s eco journey

One Kongsberg Maritime customer that not only sees the benefit of investing in wind technology, but in full integration is Tärntank, a Swedish ship owner operating a fleet of chemical tankers. In 2025, the first of five it has on order will utilise wind power, a first reference for K-Sail.

Henrik says the project highlights the practical benefits of K-Sail. He says: “We looked at the vessel, saw how it operated, tested different sail technologies and realised that for the specific operation of the Tärntank vessels, the best solution was suction wind sails. The five tankers are also of Kongsberg Maritime design –NVC 615 – so that level of integration is definitely one of a ‘whole-ship’ approach.”

“The integration of K-Sail into Tärntank’s vessel resulted in significant fuel savings and improved operational efficiency. We achieved a net saving from 9 per cent to 15 per cent with a fairly small investment.” K-Sail is about adding value and optimising any investment in wind-assist technology, offering a sustainable and efficient solution for shipowners. Its versatility makes it suitable for various types of vessels, including cargo ships, cruise vessels and offshore platforms. Through smart integration K-Sail optimises voyages, saves fuel, cuts emissions and reduces operating costs. As Henrik aptly puts it, “Our trick is to bring added value to the investment when the shipowner invests in the sails.”