Future proofing made easier

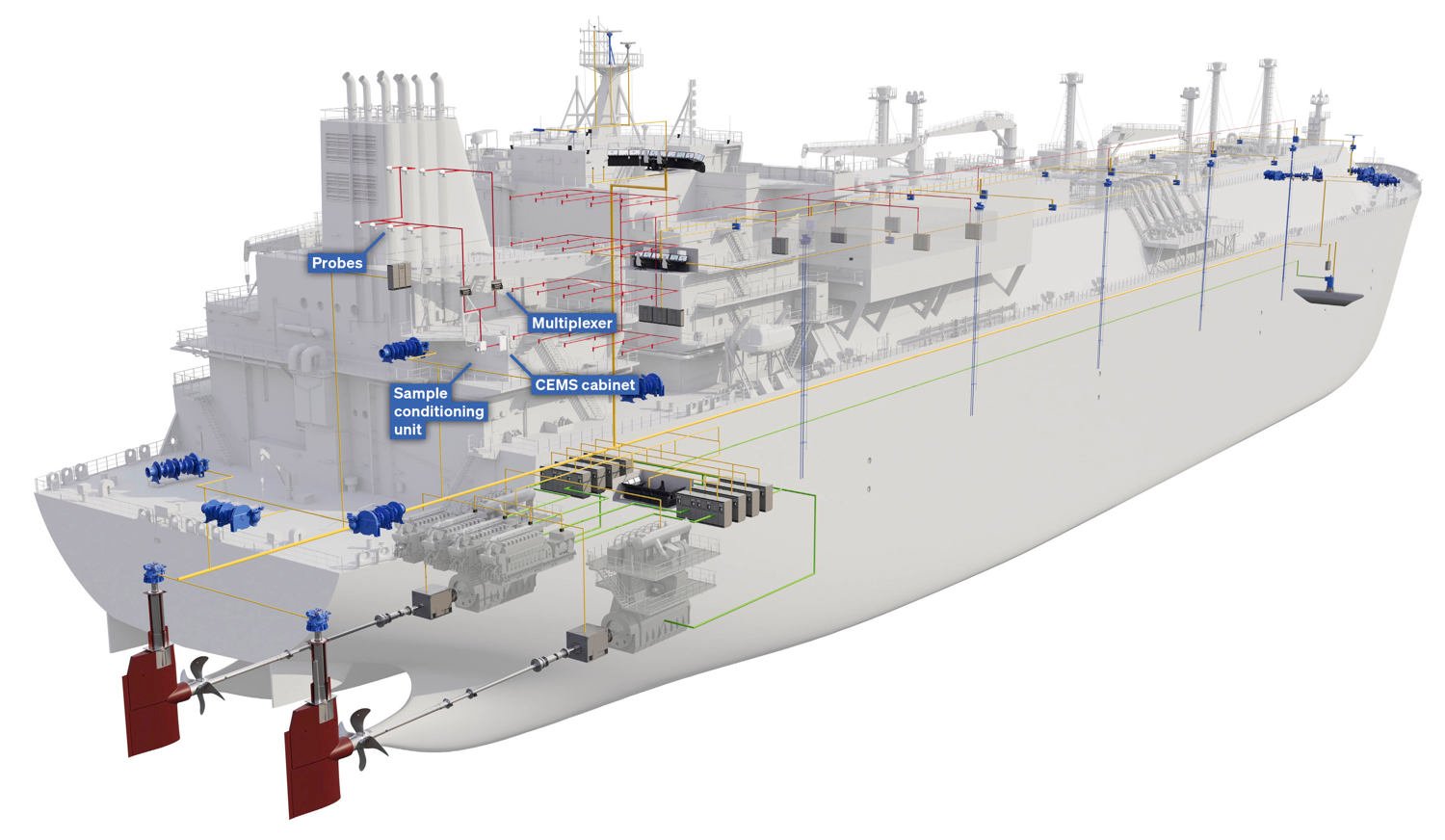

Kongsberg Maritime’s CEMS integrates tightly with the company’s K-Chief vessel automation system, which makes it much easier for a vessel’s crew to read and interpret emissions data. A single interface shows operational data along with emissions data. The system’s ability to automate and streamline the monitoring process reduces manual efforts and errors, enhancing overall operational efficiency.

The system also allows vessel owners and operators to make decisions on operational efficiency and thus focus on unexplored areas of cost savings. Real-time maintenance alerts to the crew ensure that any issues can be addressed promptly.

This helps maintaining the accuracy of the emissions data and reduces the risk of non-compliance due to equipment failure. The modular design of CEMS is flexible and easy to install, making it ideal for existing vessels as well as newbuilds.

CEMS allows vessel owners to have greater confidence in their maritime assets. As environmental regulations evolve, having a reliable and advanced emissions monitoring system in place ensures that your vessels remain competitive with

less stranded asset risk.

Randi notes that most vessel owners have yet to invest in CEMS. “A lot of vessel owners are considering fleet-wide installation,” she says, “and we have worldwide support for this technology.” Any CEMS will require regular maintenance, and Kongsberg Maritime has a global network of support centres that can assist vessel owners. Moreover, with K-Chief integration, diagnostic support can be done remotely with full cybersecurity protocols in place.

Kongsberg Maritime CEMS is a powerful part of an owner’s toolkit for future proofing fleets. By combining the data technology, integration and global support network, shipowners and operators can reliably and economically ensure emissions compliance. And that is in everyone’s interest.