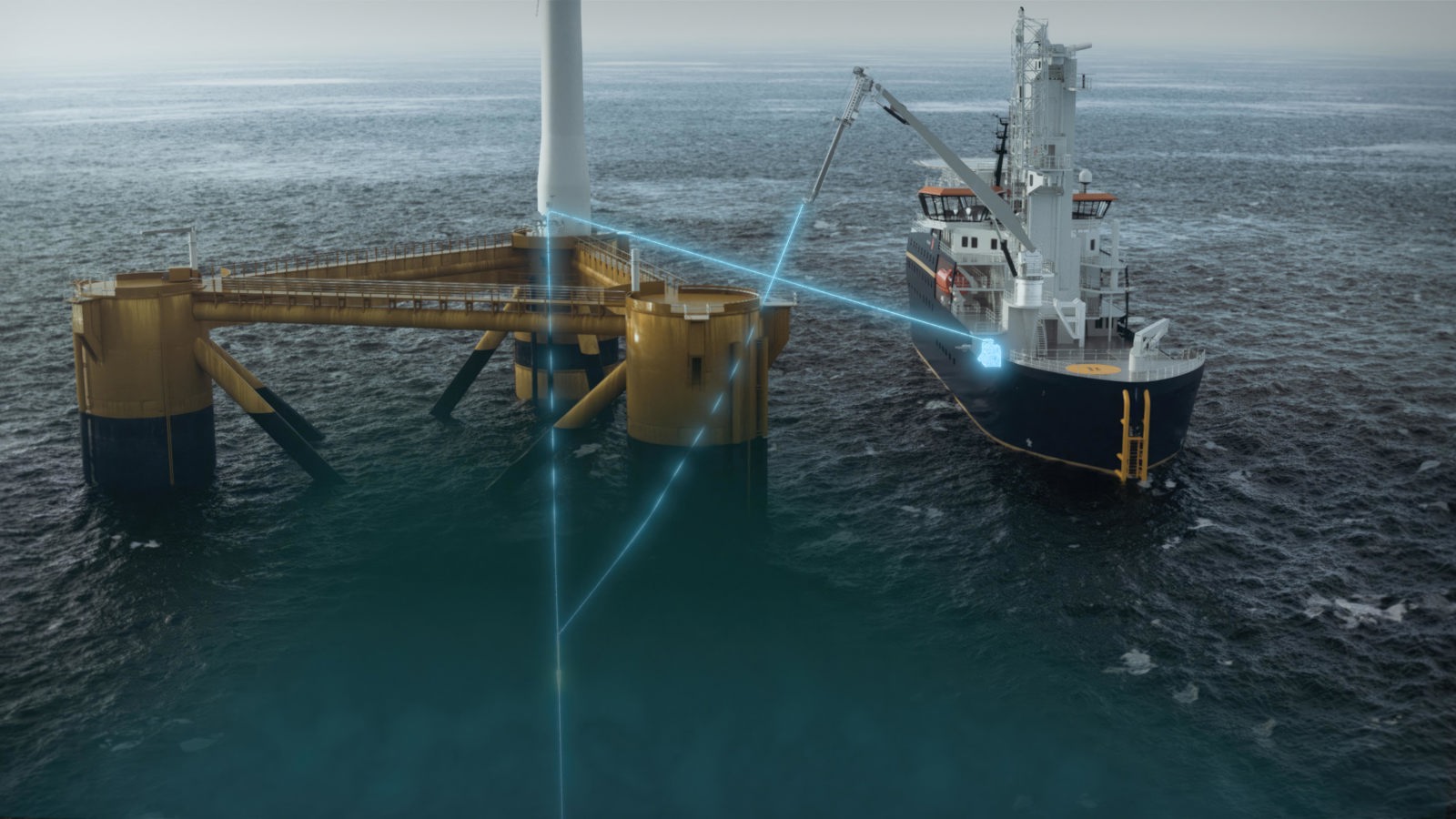

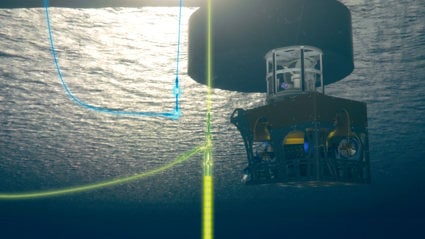

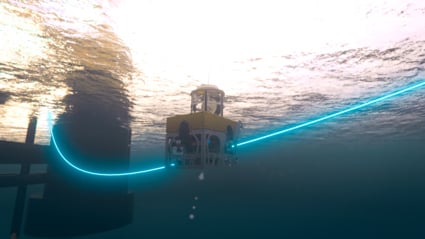

The step-by-step method shown below offers several advantages, including enhanced safety by reducing the need for personnel on the floater during the pull-in operation, and speeds up the overall rate of installation of the wind farm array.

Ottar Antonsen, Kongsberg Maritime’s VicePresident Business Concept and Advisory, highlights the broader implications: “We offer the full package of equipment and technology, from the point the floating turbines leave their construction site, up to the point at which the turbines are connected to the power grid and local substation, and everything in between.

“As the floating offshore wind market expands globally, with regions such as Taiwan, Japan, Korea, Europe and the Americas adopting this technology, the need for an industrialised process becomes evident. “We see that the way we do it today, using several types of vessels, might be okay in the North Sea where we have a well functioning oil and gas spot market. However, with floating wind being adopted globally, areas without oil and gas activity will require a different approach, with vessels designed and built for this specific role.

“Our innovative cable pull-in method is the final part of a new holistic solution to the industrialisation of floating wind installation. Together with our new approach to tow-out, anchor tensioning, mooring and hook-up, we are offering a full solution that represents a big leap forward. This range of methods will enhance safety, efficiency and operational flexibility, and support the rapid growth of this vital renewable energy source.”