How Dynamic Positioning changed offshore operations forever

Storms, waves and strong currents. Out at sea, nature’s forces can be relentless. Yet vessels can remain completely still—without dropping anchor.

Dynamic Positioning (DP) is a pioneering Norwegian technology that has made life at sea safer for over 50 years.

However, there was considerable scepticism when the idea was first introduced.

— There’s nothing better than standing up here on the bridge on a sunny day, says First Officer Bjørnar Solås (26), squinting towards the low sun on the horizon.

The bridge of the 95-metre offshore vessel Normand Drott is his regular workspace—with a view that’s hard to beat.

— It’s a workplace I wouldn’t trade for anything, he affirms.

Together with a crew of 19, he’s heading to the Yggdrasil field in the North Sea, where they’ll install anchor moorings for a drilling rig.

Bjørnar has always felt drawn to the sea. The coastal waters around his hometown of Bømlo were his first playground, and much of his childhood was spent at sea with his father. It also sparked a desire to explore.

– Choosing a maritime career became a natural way to see the world. My job has now taken me to Guyana, Mexico, Congo, Angola—places I wouldn’t otherwise have visited, he says.

ROUGH SEAS: It was aboard the training ship Gann that, at the age of 16, he first experienced what it was like to wake up in the middle of a storm. But he wasn’t scared. On the contrary—it sparked a passion in him.

Anchored by technology

Days at sea can be idyllic, but Bjørnar knows better than most how quickly the weather can turn—and how intense the workdays aboard an offshore vessel can be.– Our job mainly involves moving oil platforms in the North Sea and anchoring them in place. That’s where the DP system is absolutely essential. We couldn’t do it without it, Bjørnar explains.

Sensing the storm

Often, he can feel both the vessel and his own body signalling that rough weather is on the way. In those moments, having the DP system provides a huge sense of security. It allows him to monitor real-time data showing how the vessel is using increasing amounts of power to maintain its position.- This way, we can track wind, wave and current conditions, and see how the vessel is moving—pitching and rolling.

This information is extremely valuable when we need to assess whether we can continue the operation or if we need to stop.

- We’re very happy working with the Kongsberg Maritime systems. They’re simple and intuitive, yet advanced enough to allow us to make adjustments that improve operational efficiency.

It’s a system that’s constantly evolving and open to feedback from those of us who use it. I really appreciate that, he says.

Norwegian pioneers dared where others doubted

That Bjørnar can now place complete trust in the DP system is thanks to a piece of Norwegian engineering born under very different circumstances. The story began in the mid-1970s. The North Sea was a new Klondike—full of opportunity, but also fraught with danger. The offshore industry was emerging, yet vessels drifted uncontrollably in waves and currents. Anchors were heavy, impractical—and often outright hazardous.

But the solution came from a small inland town: Kongsberg.

Vegard Sæterlid, Kongsberg Maritime- Without DP, there would be no oil adventure.

- Without DP, there would be no oil adventure, says Vegard Sæterlid, Head of Positioning and Manoeuvring at Kongsberg Maritime.

It’s no wonder the DP system is hailed as the greatest Norwegian engineering achievement since the Second World War.

A bold idea that changed everything

Back in the late 1970s, enthusiasm was in short supply when Professor Jens Balchen from NTH (Norwegian Institute of Technology) introduced a daring concept: a system that could keep a vessel completely still in open water—without an anchor. The idea was met with scepticism. The industry doubted it. But the young professor believed in it—and was willing to take the risk.

Kongsberg Våpenfabrikk (KV) wasn’t fully convinced either. But Balchen didn’t give up, and in 1975, he managed to persuade KV to give the project a chance.

- We didn’t realise how difficult it was. That’s probably why it went so well, smiles Nils Albert Jenssen today.

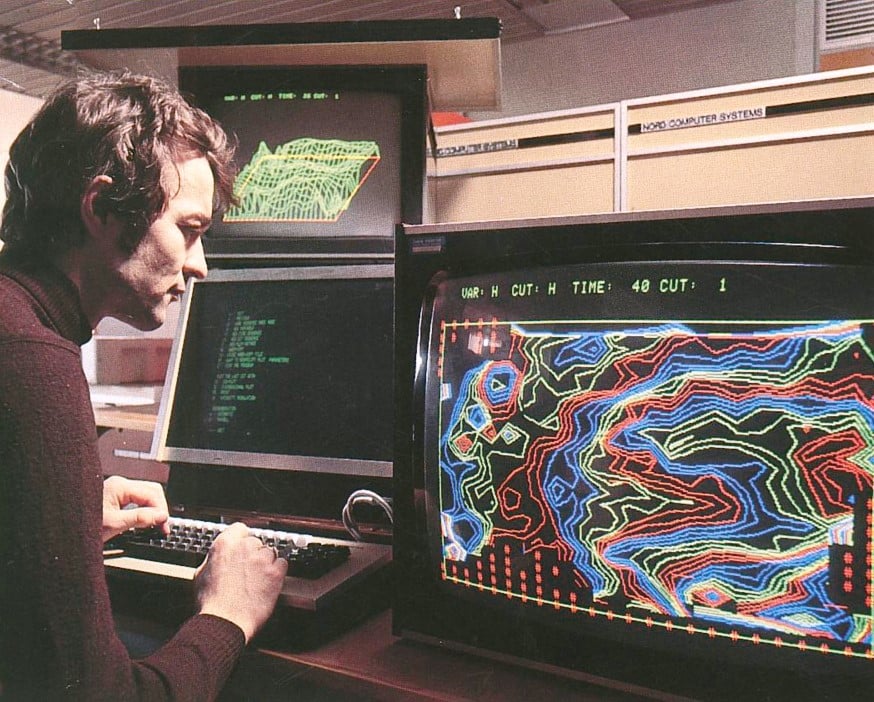

On a November day in 1975, he received the assignment that would secure his place in Norwegian industrial history: to develop an entirely new control system for dynamic positioning at sea. The newly graduated cyberneticist from SINTEF took on the challenge without hesitation, teaming up with colleague Steinar Sælid. In no time, they assembled a small team of ten to twelve people who worked day and night.

The theory was simple — but reality posed challenges. Algorithms had to be continuously adapted, simplified and improved. The result was groundbreaking: the world’s first Norwegian DP system. This marked the beginning of a technology that would go on to transform the global maritime industry.

Moon landing moment

The new system was named Albatross. On Norway’s Constitution Day—17 May 1977—it was tested live for the first time on Stolt-Nielsen’s vessel Seaway Eagle.

Tension was high. Would it work?

Then came the message from Seaway Eagle: Albatross had delivered.

“We got a huge kick out of hearing that the system worked,” says Jenssen.

“For us, it was like a moon landing.”

But even though the system was a success, the engineers’ work was only half done. A long road of improvements and refinements lay ahead.

Nils Albert Jenssen

What is Dynamic Positioning (DP)?

-

Stability in open waters

Dynamic Positioning (DP) enables a vessel to remain completely still at sea, even in challenging conditions with waves, wind and currents.

The system uses advanced position sensors, thrusters and propellers to calculate and counteract environmental forces—in real time. -

Built for precision and safety

Dynamic Positioning (DP) is used on a wide range of vessels—from supply ships and drilling rigs to cruise ships, research vessels and superyachts.

The system enhances safety and operational accuracy in demanding conditions—and has played a role in saving lives at sea. -

A global success story

Developed in Kongsberg, Dynamic Positioning (DP) has been an essential part of the maritime industry worldwide for over 50 years.

Kongsberg Maritime’s modern DP system—K-Pos DP—combines data from sensors and power systems to ensure accurate positioning and efficient operations.

From the oil adventure to the autonomous ships of tomorrow

Since those early days, development has progressed at an impressive pace. More than 4,000 Dynamic Positioning (DP) systems from Kongsberg Maritime have been installed on vessels around the world—from the most advanced offshore ships and semi-submersible platforms to cruise ships, superyachts, wind farm vessels, and aquaculture support vessels like Oddrun With.Today, DP systems are integrated with advanced weather forecasting. This enables operators to assess how long a vessel can maintain position before wind and waves force it to retreat. The benefits are tangible: helicopters can be advised exactly when it’s safe to land on a platform—avoiding unnecessary turnarounds. Gangways can be retracted in time, preventing crew from being stranded. Drilling operations become safer, as the drill string remains stable even in challenging conditions.

“This isn’t science fiction. It’s already happening,” explains Vegard Sæterlid.

Now seafarers can pick up from nursery too

The most radical development is happening onshore. The DP system is the driving force behind the shift to autonomous vessels. It doesn’t matter whether the command comes from a captain, a joystick or an algorithm—DP ensures the vessel moves exactly where it’s supposed to.

“When we move operations to land, new benefits emerge. For example, seafarers can be at home with their families and pick up their children from nursery—even while ‘at sea’. It also reduces the need for crew offshore, which is a global challenge. And safety improves,” explains Sæterlid.

Right now, there’s nowhere Bjørnar would rather work than offshore—but in the near future, he sees that changing.

“Eventually, you start to want more stability. Several of my colleagues have chosen to work onshore or in coastal shipping with shorter trips so they can spend more time at home. It’s reassuring to know that the technology makes it possible to stay in the industry while working from land,” he says. He finds it fascinating to watch the development unfold.

The technology leverages all types of networks—satellite, 5G, and low-Earth orbit satellites such as Hermes and Starlink—enabling operators to monitor and control vessels remotely, regardless of their location.

Artificial intelligence also plays a role in route planning, with systems recommending the most efficient sailing paths based on weather, currents, speed, and engine performance.

In the next phase, small autonomous vessels could patrol wind farms, recharge at the turbines, and respond when needed—eliminating the need to dispatch large ships from shore.

A strong example is REACH, a small offshore vessel operated without crew and remotely controlled from the Massterly Remote Operations Centre (ROC) in Horten, Norway, owned by Kongsberg Maritime.

“We can deploy it for up to 30 days to carry out subsea operations—including both monitoring and direct intervention on installations—with 90% lower CO₂ emissions compared to conventional vessels,” explains Sæterlid.

“REACH represents a completely new approach to offshore operations. It’s disruptive.”

Skywalker is one of Kongsberg Maritime’s newest and most exciting vessel concepts. The ship is designed and equipped for the future of the offshore wind industry, where demands for efficiency, sustainability and safety are higher than ever.

Unlike unmanned vessels such as REACH, Skywalker is a larger service vessel with crew on board.

“With DP, Skywalker can remain completely stable alongside wind turbines—even in challenging weather conditions—allowing technicians to carry out service work safely and precisely.”

A greener future

“Imagine small self-driving ferries that can be booked via mobile,” says Sæterlid.

One day, you might cross the fjord using an app. It’s fascinating to think about all the possibilities that will become available in the not-so-distant future.Or we could send out sea drones to map marine areas, instead of deploying large crewed vessels. The entire theory behind DP is cybernetics. It can be applied to anything involving motion control, explains Sæterlid.

The Technology That Saves Lives

Today, Dynamic Positioning (DP) is an indispensable part of the maritime industry. It enables vessels to operate safely under extreme conditions. It has made demanding operations simpler and safer. And most importantly: it saves lives.

For Bjørnar aboard Normand Drott, it’s about anchoring in a storm without losing control. For divers on the seabed, it’s about knowing the vessel above them remains completely still. For the offshore industry, it’s about safety in some of the world’s harshest marine environments.

Norwegian engineering hasn’t just set the standard for dynamic positioning—it has shaped an entire industry. And after 50 years, Kongsberg Maritime has no plans to give up its place in the driver’s seat:

“The entire maritime industry turns to us and asks what we at Kongsberg Maritime have come up with now,” says Sæterlid.

“What we do isn’t just about technology—it’s about making everyday work simpler, more efficient and greener. And we’re only just getting started.”

This is Kongsberg Maritime

Kongsberg Maritime is a global technology company delivering innovative and reliable solutions to the entire maritime industry.

With headquarters in Kongsberg, Norway and operations in 34 countries, we provide technology that covers every aspect of maritime automation, safety, manoeuvring, navigation and dynamic positioning – as well as energy management, deck machinery, propulsion systems, simulation and ship design.

At Kongsberg Maritime, we shape the maritime future – through technology, people and collaboration. Our solutions are in use on more than 30,000 vessels worldwide, and together with our partners we make maritime operations safer, more efficient and more sustainable.

Through continuous technological development and sharing our expertise, we strengthen the ocean economy and help address the challenges that define our shared future.