Wind Farm Support Vessel

Minimise cost. Optimise energy. Maximise performance

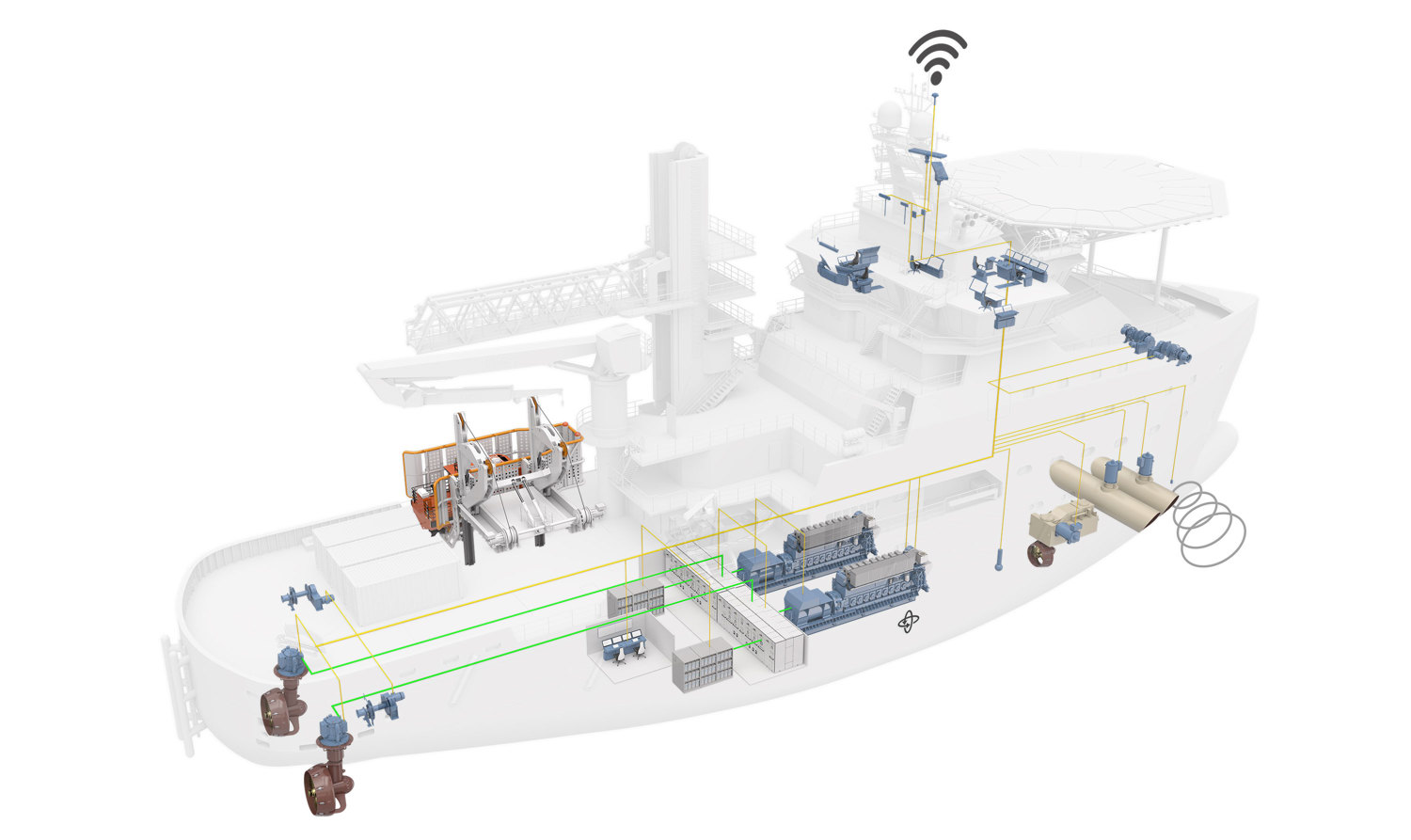

KONGSBERG’s unification of state-of-the-art control and positioning technology with energy-saving hybrid power, propulsion and handling equipment, creates a unique platform for safe, efficient and environmental friendly windfarm operations. Advanced systems fully integrated with the vessel design will introduce the operators to significant CAPEX savings, while enhanced comfort and efficiency during operation maximises the performance onboard.

Key figures

The Hybrid System with Offshore Field charging from Charging Buoys will reduce emissions from operations with up to 80%, bringing the savings due to less expensive charging from the field down with approximately 50% and increased operational efficiency due to the Boat Transfer System (BTS) that are able to launch and recovery of the technician transfer operation in larger sea states.

The KONGSBERG design integrates the critical systems to secure a stable and comfortable base for the technicians that are working on the Windfarm. The KONGSBERG Boat Transfer System (BTS) secures the handling of the Daughter Craft that transfer the technicians to and from the installations, while the advanced DP set up secures the vessels position close to the installation to enable a secure transfer of personnel via the W2W installation.

The SAVeENERGY Battery installation and the SAVeSAFE electric system in combination with the offshore charging system enables the vessel to run in almost zero emission mode for most of its operation. During Night time, the vessel will hook up to a charging buoy and charge the batteries via the the power created by the nearby windfarm. The need of fossil energy production is reduced to a minimum for back up functions.

Integration of our state of the art Propulsion units, Engines, Deck Machinery and Control and Safety Systems will reduce a number of cost elements for the OSV:

- Shipyard will save engineering hours, interface meetings, cabling and installation work, and over all reduce the risk in the project

- Ship designers will be able to tailor their solutions for specific designs and customer requirements together with KONGSBERG. An integrated solution will free up space and reduce weight. This is valid for winches, electrical systems and control systems at bridge

- Owner and operators will reduce OPEX regards to efficient installation operations. A proven life cycle management system for the delivered solution will in the long run save cost and increase visibility for the uptime of your asset.

- Shipyard, designers, owners and operators will benefit from the unique knowledge and experience Kongsberg possess after more than 30 years within demanding Offshore operations, enabled by Kongsberg contribution throughout the entire process from concept to operation.

The world´s most advanced technology systems are now available for the Wind Farm Support Industry.

Reference

KEY BENEFITS

-

Operability

The Integrated solutions from KONGSBERG secures operational efficiency and durability in challenging working conditions.

-

Performance

Vessel performance systems with innovative and comprehensive solutions unlocking the full value of all available technical information addressing engine optimization, reduction of noise and vibrations.

-

Safety

Safer operations - integrated and fault tolerant control platform and handling solution to reduce operational risk.

-

Environment

Reducing environmental impact, enhancing performance utilizing renewable energy directly from the wind farm.

Find out how your business could benefit from the world´s most advanced technology systems for the Wind Farm Support Industry.

CONNECTING WITH THE FUTURE TODAY.

MULTIPLE SYSTEMS, ONE PLATFORM, LIMITLESS POTENTIAL.

By uniting operations, energy, and handling solutions, KONGSBERG creates integrated vessel concepts that unlock powerful benefits.

The result is greater efficiency, reduced costs, intelligent asset management and a continual cycle of learning and improvement. Data is shared, understanding is enhanced and better realtime and long-term decisions are made possible, both at sea and on land.

Marine operations is integrated, the future is KONGSBERG!