K-Fleet Maintenance, Planned maintenance system

Total maintenance control. Your vessel's maintenance jobs have never been easier to manage.

A system for managing planned maintenance, including digital report forms.

Planned Maintenance System

The type approved K-Fleet Maintenance system is a tool for management of ship maintenance in both centralized and decentralized organizations.

- Short and long term planning with calendar and hour counter intervals

- Class survey, control of class jobs and certificates

- E0-Class survey items

- Electrical megger testing reports

- Dry-docking specification

- Position-based and traceable circulating components

- Digital report forms

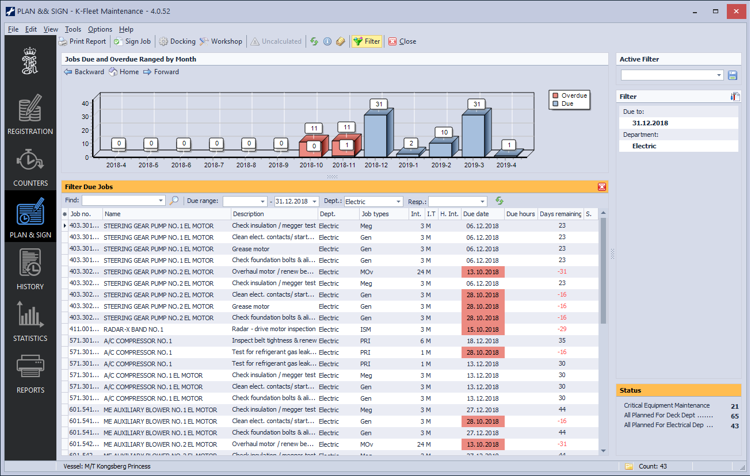

- Graphical timeline view of previous, current and future maintenance plans, split per department, responsible or job type

- Visible presentation of overdue jobs

- Maintenance jobs with subtask function (checkpoints)

- TMSA - Tanker Management and Self-Assessment reports

- Postpone reason tracking providing ability for Route Cause Analysis

- Condition code reporting for Continuous Improvement Analysis

Customized Report forms (Sold separately)

Customer specified reports on maintenance issues. One report can be several pages, and report multiple items. Each report is made customized by Kongsberg Maritime.

Key features

- Manage maintenance plan and periodic inspections from vessel or office level

- Easy updating equipment counters running hours (possibility of integration with the ship’s automation consoles)

- Easy access to the history of the work done by defining search filters

- Preview the statistics of the work done. Percentage charts work overdue

- Printing-defined report across all topics related work

- A complete tool for keeping control of the vessel’s maintenance, both planned and unplanned

- Database modifications may be carried out in the main office and on the vessel with database synchronization across locations, using a database harmonization wizard

- All changes recorded in the change log

- Calendar and hour counter intervals (specifying day, month, year, counter)

- Graphical timeline view of previous, current and future maintenance plans

- Maintenance plan, with both short and long term options

- Class survey, providing control of class jobs and certificates

- Equipment work history

- Reporting and filtering to give an overview of critical equipment and jobs

- Visible presentation of overdue jobs

- Multiple checkpoint options (checkbox, value, free text) to allow complete tracking of maintenance jobs and sub-task registration. Converting existing jobs to bundled checkpoint level reduce the number of jobs in the database

- Simplified signing process of related jobs with applicable checkpoints

- Position tracking and status records for circulating components

- Strong search and sort capabilities

- Filtering, with individual definition of filters and key performance indicators, integrated with software dashboard

- Filtering and reporting with the option of exporting to different formats (pdf, rtf, xls, xml, ods, tif etc.)

- OCIMF's required Tanker Management and Self Assessment (TMSA) statistics on overdue jobs

- Postpone Reason tracking, providing ability for Route Cause Analysis

- Condition code reporting for Continuous Improvement Analysis

Benefits

- Class approved

- Updated overviews on-board vessel and on-shore

- Easy workload distribution

- Integrated with K-Fleet Purchase

- Powerful reporting

Services and support

-

24/7 Technical support

Our 24/7 technical support team is there to help at any time, day or night, wherever your vessel is.

-

Conversions, retrofit and refit

We understand the importance of having the right parts, available in the right place, at the right time.

-

Training

Ensure that your crew is properly and thoroughly trained. This will reduce operational risk, downtime and maximise return on asset investment.