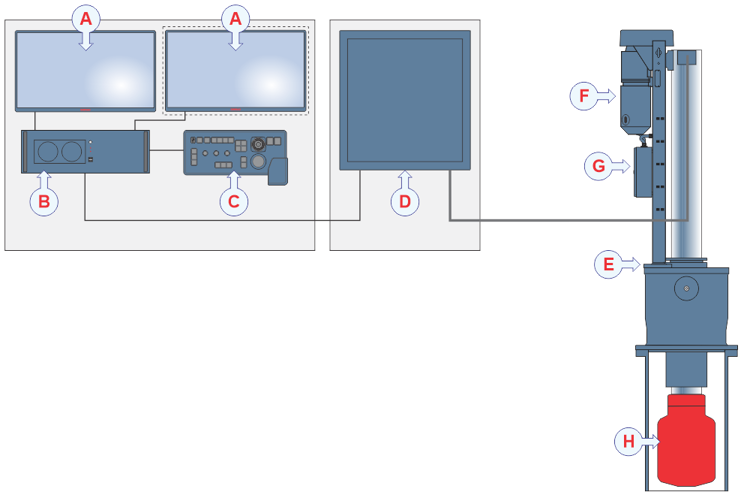

System diagram

The Simrad SX90 comprises a Processor Unit (computer) with an operating panel, a transceiver and a hull unit with the transducer.

(A) Display (the second display is optional)

(B) Processor Unit (computer)

(C) Operating Panel

(D) Transceiver Unit

(E) Hull Unit

(F) Hoist motor

(G) Motor Control Unit

(H) Transducer

The cable between the topside Processor Unit and the SX90 Transceiver Unit in the sonar room must be a high-quality Ethernet cable. This cable can be purchased locally or ordered from us.

Return to product page

[ Simrad SX90 ]

Display

A display is a required part of the sonar system. For best readability, you must protect the display from glare and have the correct height and angle. The display is not a standard part of the delivery. This is a commercial item that you can purchase locally.

Processor Unit

The Processor Unit comprises a single powerful maritime computer. We provide it as a standard part of the delivery. It serves several functions.

The Processor Unit handles the advanced signal processing required to present the information on the display, allowing you to control the sonar. It provides the graphic presentation of the sonar views and the created images; it holds the menu system, communicates with the transceiver circuitry, and reads information from the peripheral units. The computer is based on a commercial design, but the software and hardware have been specified and assembled specifically to meet the sonar requirements.

Operating Panel

The Operating Panel allows you to access the most frequently used functions quickly and efficiently. It also provides a trackball and the necessary control buttons to operate the menu system.

Transceiver Unit

The Transceiver Unit contains the transmission and reception circuitry for the sonar.

The transceiver transmits acoustic energy through the water. This transmission is commonly referred to as a "ping". After each transmission, the transceiver receives the echoes from the targets in the water or the seabed. These echoes are filtered and amplified and then converted into digital format.

The connections for power and communication are made under the cabinet. The transducer cable is connected using a large proprietary plug on the side wall.

The Transceiver Unit has been designed to be mounted on the bulkhead in the sonar room. It is fitted with powerful shock absorbers to withstand the violent motions of a vessel at sea.

Hull unit

The hull unit is designed to lower the transducer below the ship's hull when you want to use the sonar system. When the sonar is turned off, the transducer is hoisted for protection.

The hull unit is a mechanical construction. It is mounted on the top of the installation trunk. The installation trunk penetrates the ship's hull and allows the transducer to be lowered into the sea. The hull unit is normally located in the forward part of the vessel. This location is recommended to avoid the noise from the propellers and the engine.

[ Several different hull unit types are available ]

Return to product page

[ Simrad SX90 ]