Training specialist Kongsberg Maritime is experiencing a record high increase in demand for training. In Houston alone, the number of course participants has doubled in the past three years. The department recently had to expand, opening two new classrooms.

-

Text:CHRISTINA FJELLSTAD

Photo:CHRIS CURRY

-

Ove Ronny HaraldsenGroup Communication Manager

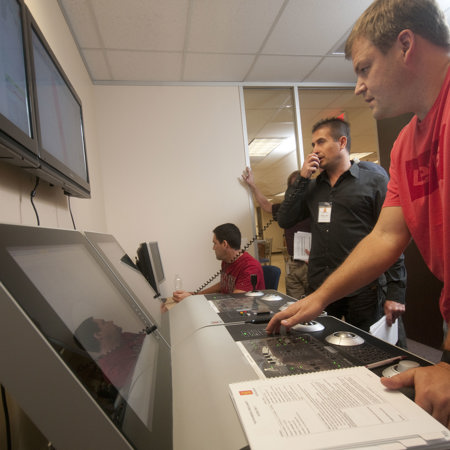

What do you do if there is suddenly a complete blackout on-board a drill ship?” This question comes loud and clear from instructor William Westmoreland. He is in one of Kongsberg Maritime’s classrooms in Houston, teaching six course participants from Transocean.

This is the first day of a tailor-made, so-called DP Power Simulator course, involving risk management in the event of a power fault when using dynamic positioning (DP). In order to identify the level the participants are at, William starts the four-day long course with a quiz. As is always the case, some participants have the answers while others do not.

AN INFORMAL ATMOSPHERE

William has worked as an instructor for KM Houston since January 2009 and has many years of experience as an instructor from the American Navy. His experience shows. For William, an important factor is creating a positive and informal atmosphere by encouraging the participants to interact.

He makes regular use of the board, in addition to PowerPoint presentations with text and illustrations. William is aware that the level of his course participants will vary, and that it is important to adapt the message of the course to the participants. He therefore concentrates on communicating the message in a way which can be easily understood.

LEARNING BY DOING: With the simulator, the course participants will experience the physical effect of a stressful situation. Even though the more extreme scenarios seldom occur, it is essential to train crews for every possible and impossible situation.

“It’s important to let the participants know that they can ask questions, no matter what level they work at in an organisation. The people taking part in these courses come from very different work backgrounds. I may have, for example, senior and assistant DP operators on the same course. Some people find it difficult to ask questions, either because they are new and don’t dare or because they are senior operators and don’t want to show the others that there are things they don’t know,” he explains.

INCREASED FOCUS ON SAFETY

The PoweSim course was developed in cooperation with Transocean in 2005 and has been held regularly since then for the company’s employees, as part of an internal training program. Prior to participation, the majority of those taking part have completed one basic and one advanced course in the use of DP.

Transocean wanted their employees to know more than just how to operate a DP system. An important part of this course therefore involves drills in potentially hazardous scenarios which may occur on-board a vessel, such as a blackout or extreme weather conditions which require specific knowledge.

The goal is for the participants to take the knowledge gained from the course back to their vessel, and use this as the basis for discussions on how to handle such situations.

“The majority of scenarios we use in the course will never be experienced. Fortunately,” says William.

So why spend four days drilling scenarios which most probably will never occur?

“Safety is of extreme importance and is subject to an increasingly intense focus. Onboard a vessel, you have to make decisions under significant pressure, and this course has been based on actual incidents that have occurred. Although the most extreme scenarios seldom occur, the crew has to be prepared for every possible and impossible situation. Transocean realised that most problems during DP operations were caused by human error, not actual faults in the system. They believed that this was due to a lack of knowledge on how to handle different situations, thus the development of this course. It provides employees with the opportunity to learn by doing, making them better equipped to deal with any crises in the future,” explains William.

THE PHYSICAL IMPACT OF STRESS

Simulators are essential tools for this and a number of other courses held at the training centre. They allow participants to work through potentially hazardous situations but in a safe environment, which would not be possible on-board a vessel for both safety and economic reasons.

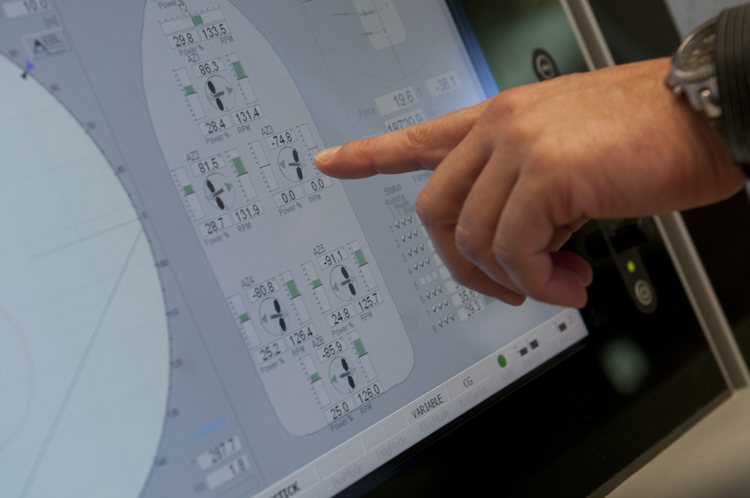

The first simulator drill involves steering a drill ship towards an existing well, positioning the BOP (Blow Out Preventer) directly over the well-head and connecting then locking the two together.

SEAFARER ON LAND: “This is a super form of training,” claims Kevin Murphy, who believes that the course provided by Kongsberg Maritime will be a huge help in his job as DP operator for Transocean.

Each drill has specific operational criteria for the individual well and information on the DP system status which the participants have to utilise as a basis for decision-making. Examples of such information may include the number of thrusters operational and whether the Power Management system, which is used to ensure sufficient power for the DP system, is functioning as normal.

As the participants become accustomed to the situation, they will be met with increasingly difficult criteria to handle. In order to achieve a high level of authenticity, the participants are assigned different roles.

Three participants share the hot seat while the other three observe. One of the three is captain, the second is in charge of the monitoring systems and the third is the DP operator. Although the course instructors are actually present in the room beside the simulator, it is imagined that they are in another part of the vessel and communicate with the participants on the “bridge” via an internal calling system. A camera situated in the drill room provides the instructors with a full overview of proceedings.

“Calling the captain. We appear to be drifting a bit now. What do you intend to do about it?” asks William, as the pressure increases on the “bridge”.

This requires a rapid decision in order to ensure proper connection with the well-head. There’s no doubt that the participants learn a lot through trial and error. After every person has taken a turn in the hot seat, each drill is reviewed in detail to identify what could have been done differently.

“This is a super form of training,” claims DP operator Kevin Murphy.

VAST SAVINGS

“Using simulators for training is cost-effective. An actual incident could cost millions of dollars and could have a major impact on the environment. This training provides us DP operators with an idea of what could actually go wrong out on the field. This course is most definitely of great value for my job,” continues Kevin Murphy, with the support of Offshore Installation Manager Chris Wokowsky.

“When you’re standing there in front of the simulator, you can really feel and experience what it would be like to go through such a stressful situation. You really feel like it is actually happening.”

“It’s much more valuable than just sitting looking at a PowerPoint presentation throughout the entire course. I guess what the instructors are trying to tell us is that, if we fail to diagnose the problem properly at the outset, it could result in a domino effect with severe consequences,” he continues.

FOUNDATIONS FOR FUTURE GROWTH

The course for Transocean is merely one of innumerable courses offered at the KM training centre in Houston, and one of few tailor-made for a specific customer. The majority of courses are open to a number of different customers.

The centre provides training in both basic and advanced use of dynamic positioning systems in addition to HiPAP subsea positioning systems and the K-Chief marine automation system.

As the largest and first training centre outside of Norway, Houston has witnessed a significant growth in demand over its 11-year history. During its first year of operations, 2000, the centre offered 36 courses and had 236 participants.

In 2011, the corresponding figures are 145 courses and 870 participants. The department now has six employees and expects to recruit a further two instructors in the near future. According to Training Manager in Houston, Alaric Durkan, there are several reasons behind this growth.

“Primarily, it is a question of location. A number of our customers are located in Houston. What’s more, there are plans for the construction of a number of drill ships and other DP vessels for operations in the Gulf of Mexico region up to the end of 2013. This all results in a higher demand for more qualified operators and technicians. We also expect to see an increase in legislation around safety and competencies on-board such vessels. Basic training and familiarity with the systems on-board are an important factor here. There is a trend now towards being proactive, not waiting for new regulations but taking the first steps now towards procuring good training for employees,” explains Alaric.

QUALITY TRAINING

Alaric believes that training in general plays a decisive role in achieving the successful operation of a vessel and to increase safety on-board.

“Our students are all highly intelligent, experienced ship operators and technicians, but still require specialised technical and operational knowledge in order to safely operate and maintain the systems we supply. By providing them with quality training according to strict guidelines for both content and execution, we are attempting to close the gap between the basic technical understanding these people have and use of the specific systems,” explains Alaric.

With the opening of two new classrooms and a highly qualified staff, Alaric is confident that the training centre in Houston is well prepared for the increase in demand.