Minimise non-productive time, optimize efficiency, maximize safety

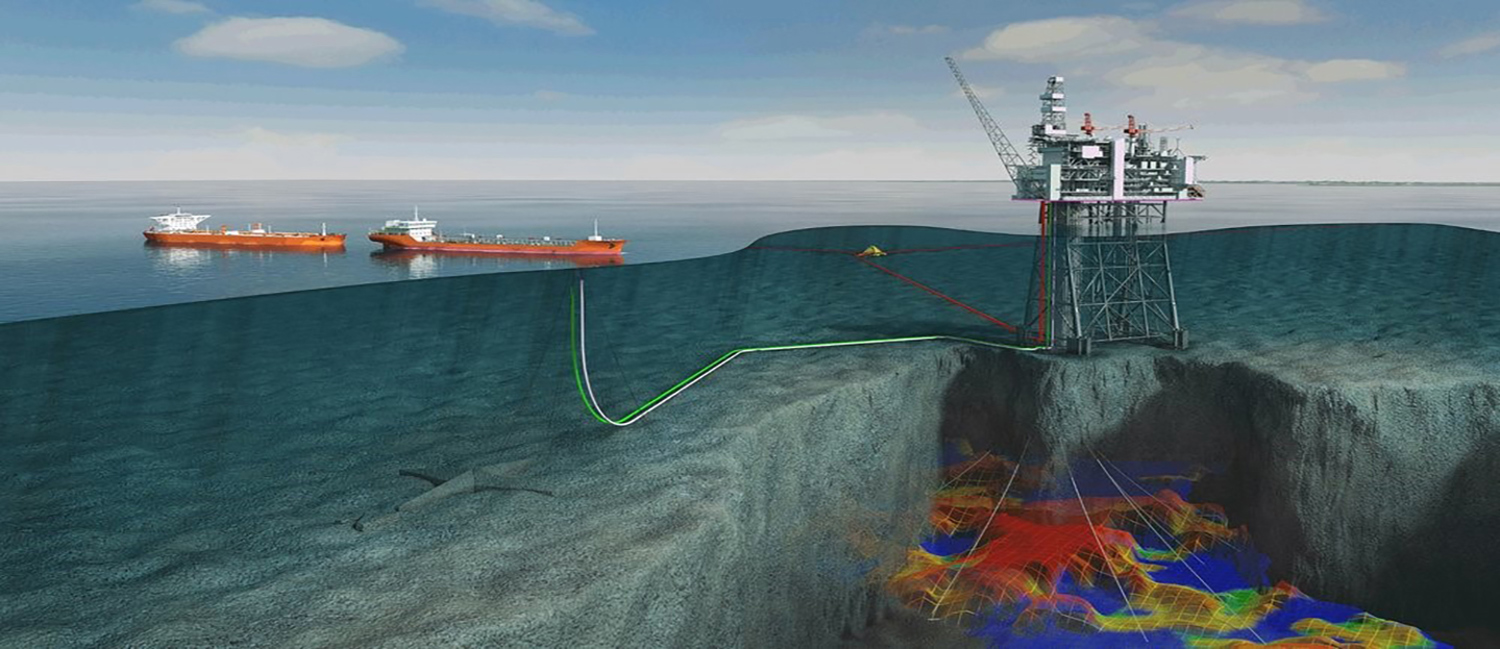

Kongsberg Maritime integrated solutions for production units are the most cost effective route to improving the efficiency of your operations in the market today. Through deep interconnection of diverse equipment and technologies, we enable you to implement workflows to lower lifecycle costs, both CAPEX and OPEX, while reducing your environmental footprint.

Modern production units are defined both by their increasing complexity and a need to perform with optimal efficiency and sustainability, often in extreme environmental conditions. KONGSBERG addresses these challenges through smart, future-proof integration between all systems onboard, robust system design and efficiencies that both reduce cost and enhance performance.

KONGSBERG solutions for production are designed to improve the performance of a production unit, empowering you to increase efficiency, lower costs, improve safety and lessen the environmental footprint of energy E&P. Additionally, deeper integration of diverse equipment and technologies unlocks the potential for reduced time for installation, commissioning and testing, bringing significant efficiencies to the engineering stage of your asset.

The unique integration of state-of-the-art control and safety systems, along with proven information management from a single highly experienced supplier can reduce cost elements for a production unit throughout the entire lifecycle.

- Engineering can tailor their solutions for specific operational requirements together with KONGSBERG. Seamless integration can free up space and reduce weight, allowing for smarter, more efficient production unit designs.

- The shipyard can enjoy a lower risk profile for the project, save engineering hours with significantly reduced cabling and installation work, as well as reduce hundreds of hours spent on interface meetings in the early stages.

- The owner and operators can reduce OPEX by establishing more efficient operations. A proven life cycle management system for the delivered solution can, in the long run, lower costs and increase the uptime of your asset.

-

Operability

A user-friendly and intuitive human machine interface across diverse systems empowers operators to work safely and effectively, while a powerful Information Management System enables seamless collaboration with experts on shore.

-

Productivity

Sophisticated advisory and situational awareness systems extend your operational window by providing the data and insight required to make the right decisions quickly. Operational Guidelines also improve operators understanding of the key limiting factors they face.

-

Efficiency

Deep integration between Safety and Automation Systems and future proof information management systems enables a tangible decrease in non-production time, increased safety as well as lower CAPEX and lifetime OPEX.

-

Performance

Unlocking the potential of your technical data is key to improving operational performance. Powering our comprehensive advisory functionality, integrated data is analysed with historical data on a single Information Management System, making it much easier to maximise performance and reduce costs.

-

Safety

Achieve full situational awareness with our complete Integrated Safety System. High integrity and easy-to-understand safety solutions secures safe intervention in hazardous situations and reduces human errors.

-

Environment

A KONGSBERG Full Picture delivery mitigates the environmental footprint of a production unit, while our advanced, user-friendly advisory systems minimise the risk of pollution, and our advanced energy control technologies reduce energy consumption, and resulting emissions.